Solutions to the 10 most common industrial noise problems

Our original “Top 10 noise control solutions” was ranked the #1 industrial noise control document on the web via the UK HSE website. This is the update, many years on…

These are 10 simple engineering industrial noise control techniques with wide application, providing substantial noise reductions quickly at low cost with no effect on operation or hygiene. They are not only considerably more sustainable than traditional palliatives such as enclosures (towards net zero "Greener Quieter" benefits) but they can often be self-financing…

Simply knowing these techniques exist can change the thought processes associated with noise control from a negative view ("enclosures and silencers that create maintenance, cleaning and productivity problems") to the understanding that noise control is just good engineering with a little noise-specific knowledge. This can have a dramatic effect on noise risk management.

We also provide rapid, worldwide noise control advice and 2nd opinions by email via our "Remote Control of Noise service" that cuts typical noise control project costs by 50% - 80%.

Download the Top 10 noise controls pdf with sound files here >

Noise control techniques - index

Vibration control = noise control

1 Vibration damping: reduce noise from guards, hoppers, conveyors, tanks…

2 Vibration isolation pads:isolate motors, pumps, hydraulics from noise amplifying sounding boards …

Fan noise control

3 Fan installation and efficiency: maximum efficiency = minimum noise – fan installation best practice guide

4 Aerodynamic fan noise control – silencing without silencers: retro-fit modifications = less noise + higher efficiency

Pneumatic noise sources

5 Pneumatic exhaust silencing: efficient attenuation with zero back-pressure

6 Pneumatic nozzle noise reduction: efficient nozzles that produce less noise and use less air for the same performance…

Machine noise control

7 Chains and timing belt noise:simple modifications to reduce noise levels

8 Electric motor noise: some are easily modified and some should be sent back due to excessive noise

9 Hydraulic power pack noise: many are designed to maximise noise levels – easily corrected

Existing Machine Guards

10 Convert to acoustically effective guards: existing safety guards can often be modified to make them effective acoustic guards

Get Expert Advice

Adapting and applying the techniques: often free by email.

Your problem may already be solved

Search our worldwide best practice options

Remote Diagnosis

Email us a video from your smartphone for free evaluation of best practice

1 Vibration Damping to reduce noise

The noise from mechanical sources is caused by the vibration of plant elements such as machine frames, panels, gears, casings, floors, castings etc. Damping involves dissipating a proportion of the vibration energy in relatively thin panels to reduce the level of vibration and hence the radiated noise. Very widely applicable, it also reduces fatigue which can reduce maintenance costs significantly.

Typical applications

Chutes, hoppers, machine guards, panels, conveyors, tanks…

Benefits

Low cost, large noise reductions, rugged, hygienic.

Vibration damping techniques

There are 2 basic techniques:-

i) unconstrained layer damping where a layer of bitumastic (or rubber or similar) high damping material is stuck to the surface

ii) constrained layer damping where a laminate is constructed in situ – by far the better technique

Unconstrained layer damping involves gluing proprietary high-damping material to thin metal panels. As the panel vibrates, it bends, stretching the damping material and some vibration energy is dissipated as heat. Constrained layer damping, on the other hand, traps the high-damping material between two metal sheets to create a laminated sound-deadened panel. Under vibration, the whole volume of the elastomeric damping material is sheared, dissipating most of the vibration energy. As a result, constrained layer sound damped steel (SDS) is c x30 more efficient than conventional damping treatments. SDS also avoids the hygiene, wear and "peeling" problems associated with stick-on damping.

Either re-manufacture steel (or aluminium) guards, panels or other components from commercially available sound damped steel or buy self-adhesive steel sheet from the supplier. The latter can simply be stuck on to existing flat components (inside or outside) covering c 80% of the flat surface area to give a 5 - 25dB(A) reduction in the noise radiated (use a thickness that is c 40% to 100% of the thickness of the panel to be treated).

Limitations

The efficiency falls off for thicker sheets. Above c 3mm sheet thickness it becomes increasingly difficult to achieve a substantial noise reduction.

Vibration damping examples

There are many successful applications in the food and pharmaceutical industries for noise control using high-performance damping (stainless sound deadened steel in particular as there are no hygiene implications for the treatment). Examples include weighing machine hoppers (10dB(A) noise reduction), vibratory feeders and conveyors (5 - 15dB(A) reductions) cowls and safety guards (3 - 9 dB(A) reductions) and complete close-fitting enclosures (e.g. homogenisers). In the case of vibratory separator noise reduction when grading confectionery, diagnosis showed that a major noise source was a large thin sheet distribution dome. Forming this component in stainless sound deadened steel contributed significantly to the overall noise reduction of 16dB(A) (from 105dB(A) down to 89dB(A)). Moreover, this modification could be incorporated into standard production machines at low cost.

Damping chiller panels

This chiller noise included tonal components radiated by the frame and panels. The conventional treatments for these types of unit are silencers plus (often) an extensive acoustic barrier. Not only are these high cost, but they can reduce the efficiency of the chillers and cause access problems for maintenance.

In this case, we used a combination of acoustic absorbent and retro-fit constrained layer damping to reduce the noise by 8dB(A) at very low cost and with no effect on system performance or efficiency.

Download the Top 10 noise controls pdf with sound files here >

Practical Design / Supplier

Constrained layer damping can be retro-fitted very easily for many applications. However, there are cases where some engineering development is required to get the most out of the technology e.g. building it into new or updated plant and machinery or combining with other noise control measures.

There are also design practices that should be used in forming, welding and in the choice of materials for more complex applications. Contact us for help in this area.

Supplier: SoundDampedSteel: www.sounddampedsteel.com +44 (0) 191 259 0700

Manufacturer of a wide range of constrained layer damped galvanised steel, stainless steel, aluminium etc. Send drawings or templates for the damping areas and cut sheets can be supplied. Alternatively, you can buy complete sheets for local fabrication.

2 Vibration Isolation Pads

Vibration transmitted from machinery into “lively” structures such as steel beams and plates is then radiated very efficiently as noise. In effect, you have bolted your vibration source to a loudspeaker which amplifies the sound. Isolation pads provide a very simple and low cost way to reduce the transmission of vibration.

Vibration isolation applications

Machine feet, motors, pumps, bolting sources to steel beams or mezzanine floors…

Benefits

Low cost, large noise reductions, rugged.

Technique

Vibration isolation need not involve steel springs or rubber bushes. In many simple cases, mounting motors, pumps, gearboxes and other items of plant on rubber bonded cork (or similar) pads can be a very effective way to reduce the transmission of vibration and therefore noise radiated by the rest of the structure. This is particularly the case where vibrating units are bolted to steel supports or floors.

A high percentage of plant ostensibly “isolated” in this way is not actually isolated as the bolts short-circuit the flexibility provided by the pads. Any rigid connection across the pads will compromise the vibration isolation. In order for the vibration isolation pads to be effective, additional flexible elements (usually thinner layers of the same vibration isolation material) must be fitted under the bolt heads with load-spreading steel washers or plates as shown in the figure. Do not over-tighten the bolts, but make sure you use nyloc nuts or thread locking compound.

Limitations

Short-circuiting by bolts or other rigid connections is the most common issue. This approach does not generally reduce low frequency vibration significantly, but it is very effective at higher frequencies (above c 200Hz). If pumps, motors etc are bolted to steel plates, frames or tanks, then these behave as loudspeakers. The isolation prevents the transmission of the higher frequency vibration components, reducing the noise. However, if the source is bolted to the planet (e.g. concrete floor), then the isolation will not reduce the overall noise level – concrete floors only radiate low frequency sound.

Examples

Power press noise control

A high-speed strip-fed press used to blank electrical trip-catch components generated operator noise levels of 101 dB(A) Leq (at 270 strokes/minute) in a relatively quiet area. The manufacturer had fitted an enclosure round the top of the press to little avail as it reduced the press noise by only 3dB(A). Thus was because the press legs themselves are welded boxes that were behaving as large loudspeakers, radiating the vibration from the blanking process very efficiently as noise. Consequently, half of the noise source on the press was outside the fitted acoustic enclosure.

The press frame was isolated from the fabricated legs by inserting 6mm composite pads between frame and legs as shown in the photograph. This process took a couple of fitters half a day and reduced the operator noise level by 9dB(A).

Motor-pump unit vibration isolation

These units are well isolated from the concrete floor using conventional steel springs. However, the pumps and motors are rigidly bolted to thin steel formed plates which behave as noise radiating loudspeakers.

Provided the coupling alignment is not a problem (if it is, then you can fit a ladder frame to maintain alignment), fitting AV pads under the motor and pump typically reduces the radiated noise by 10dB or more. Alternatively, laminate the steel plate to damp the vibration.

Download the Top 10 noise controls pdf with sound files here >

Suppliers: effective isolation pads and materials are available from:-

http://www.tiflex.co.uk/tico/tico_s.html

3 Fan Noise - Installation Affects Noise and Efficiency

The geometry of duct runs into and out of fans has a very marked effect both on fan efficiency and on the noise produced. Noise is generated by turbulence in the flow – which is wasted energy.

Typical applications

Axial flow or centrifugal fans - ID, extract, LEV, chiller, HVAC, cooling tower etc. More fan noise reduction examples >

Benefits

Increased efficiency reduces both running costs and noise.

Fan Noise Reduction - installation techniques

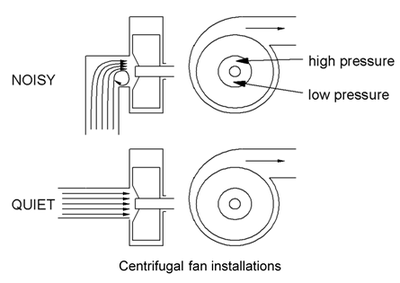

Running a fan at maximum efficiency coincides precisely with the minimum noise level. Any fan installation feature or geometry that tends to reduce fan efficiency is therefore likely to increase noise

Two of the most common examples are bends close to the fan (on the intake side in particular as fans tend to be more sensitive to inlet flow conditions) and dampers (close to the fan intake or exhaust).

Ideally, for maximum fan efficiency and minimum noise, make sure there is at least 2 - 3 duct diameters of straight duct between any feature that may disturb the flow and the fan itself. In addition, you can make use of bell-mouth intakes to smooth intake flow. 3 - 12dB(A) noise reductions are often possible by ensuring that this approach is implemented.

Taking these two examples or poor fan installation geometry:-

- the bend immediately into the intake will significantly affect fan noise and efficiency

- fitting the damper directly to the fan outlet means that the higher air velocity through some of the vanes will increase noise and reduce efficiency

Fan noise is roughly proportional to the 5th power of fan speed. Consequently, in many cases it is possible to achieve a large noise reduction by reducing fan speed slightly via invertors, by changing control systems or pulley sizes and re-setting dampers. This process can also reduce running costs as well as noise levels.

All else being equal, this table provides a guide to the trade-off that can be expected between noise level and fan speed.

For example, if you can reduce the speed of a fan by 20%, then you reduce the noise output by 5dB – which is a 68% reduction in the noise.

Limitations

The main limitation to this approach as far as geometry is concerned is that it will often take up more space as you need to ensure that there are straight duct runs into and out of the fans.

However, it is often possible to work round these issues to get close to the ideal flow conditions with shorter duct runs. Our experience means that we can often provide details of techniques and geometry changes that will provide efficiency gains. In the case of large fans, we can model the flow and suggest alterations that can markedly improve fan efficiency to reduce running costs. Contact us to discuss

Download the Top 10 noise controls pdf with sound files here >

4 Aerodynamic Fan Noise Reduction

Fan installations generate tonal and broadband noise. Tonal noise can be an occupational (overall level and “nuisance”) and an environmental noise problem – annoying nearby residents. Aerodynamic noise control techniques are based on retro-fitting aerodynamic and acoustic elements inside fan casings and associated ductwork. This is low cost and can provide significant improvements in fan efficiency compared with conventional silencing – or even compared with the unmodified fan i.e. it is worth fitting for efficiency gains even if noise is not an issue.

Whilst this approach relies on specialist knowledge for both the design of the modifications and the predictions of the attenuation, the knowledge that this award winning Quiet Fan Technology is available can not only dramatically reduce costs, but it can also reduce energy consumption.

Typical fan noise attenuation applications

Axial or centrifugal flow fans (from 10cm to 4m diameter).

Benefits

Low cost, rugged (no maintenance for the life of the fan), fast, hygienic. It often results in increased fan efficiency (10% - 25% improvement over conventional silencing) that can contribute towards net zero sustainability goals by reducing power consumption and therefore running costs.

Techniques

It is based on a similar approach to that used in Formula 1 where teams invest heavily in the design of aerodynamic aids to control the airflow round their cars. As fan noise is the sum of the turbulence generated pressure fluctuations in the air shed by the blades, we have developed a range of aerodynamic inserts that are installed inside the fan casing to smooth the flow. This reduces the pressure fluctuations – and hence the noise – at source without introducing the back-pressure often associated with silencers.

This not only reduces the tonal noise travelling down the intake and exhaust ductwork (typically by 10dB – 20dB), but also the noise passing through the fan casing. This may not only eliminate the need for silencers, but also the need for acoustic enclosures or lagging. In a significant proportion of cases, this approach can actually improve fan efficiency which means that it pays for itself in reduced running costs.

In addition, as the low frequency noise has been reduced at source, it is also often possible to insert low cost, purpose designed acoustic elements into existing ducts and stacks that provide a substantial reduction (10 – 30dB) in the broadband noise without affecting system efficiency.

Limitations

The amount of broadband attenuation that can be installed without fitting silencers depends on the local geometry of the system.

Examples

Can extract and chopper fan noise attenuation

The high level of noise from 3 new fan extract systems for aluminium cans was reduced by 22dB(A) and the tonal noise by 23dB (99.5%) by designing aerodynamic inserts that were fitted inside the fan casings. Despite the requirement for the cans to pass through the system to be shredded by the fan blades, these modifications reduced the tonal content of the noise without any loss of efficiency (unlike silencers) and with no maintenance requirements for the lifetime of the fans.

This solved both the environmental and occupational noise problems at a stroke.

Moreover, the installed cost was only c 10% of the previously proposed conventional noise control measures that included bespoke silencers, acoustic lagging and enclosures. The modifications were installed with a downtime of less than 1 day.

Drier Fan Silencing

Post modification, the blade pass tone was reduced by 20dB (99%), eliminating the noise problem. In addition, there was a 6% (16kw) reduction in fan energy consumption (saving £7625 p.a.) – which meant that the noise control project paid for itself in a few months. This is in stark contrast to the £100k of conventional noise control measures originally proposed. This capital cost was reduced to <£7k and the £8k or more additional running cost from the reduced fan efficiency due to additional silencing was turned into a total running cost saving of around £16k p.a. over the original proposal using conventional techniques. One of many reduced energy consumption noise control projects.

Combustion fans; HVAC Chillers; Extract fans etc…

Combustion fan modified overnight to reduce the tonal noise by 22dB and the overall noise by 9dB(A); 15dB(A) chiller noise reduction at a cost of £40k compared with £300k conventional without affecting efficiency…

More details, including sound files are available at Fan Noise Reduction

5 Pneumatic Exhaust Silencing

Poorly or unsilenced pneumatic exhausts are a very common feature on many sites. Rumours also abound that silencers can introduce unacceptable back-pressure, reducing performance. There is no technical reason for unsilenced exhausts – zero back-pressure silencing giving attenuations that are 10dB – 20dB more than that achieved via commonly used silencers are easily achievable.

Typical Pneumatic Exhaust Attenuation Applications

Pneumatic cylinders, valves, pumps, pressure release valves… Note: a well-designed silencer can have zero back pressure

Benefits

Low cost, large noise reductions, no impact on performance

Technique

Almost invariably it is possible to reduce pneumatic exhaust noise permanently by 10 - 30dB by fitting effective silencers. The following are the practical points that can make the difference between success and failure:-

back-pressure: for a well-designed silencer, the performance bottleneck is often the coupling – eliminated by fitting a larger coupling - and silencer

clogging: fit a straight-through absorptive silencer that cannot clog (and has no back pressure)

multiple exhausts: manifold the ports into a single, larger diameter pipe fitted with either a specialist straight-through silencer – or the rear silencer box from virtually any make of car (from your local “Quick-Fit”). Typically 25 – 35dB(A) reduction.

Limitations

None.

Download the Top 10 noise controls pdf with sound files here >

Suppliers: effective pneumatic exhaust silencers are available from:-

http://www.silvent.com/en-uk/products/?group=1908-safety-silencers

https://www.goodhanduk.co.uk/Catalogue/Exair-Air-Products/Air-Silencers/Straight-Through-Mufflers

http://www.servais.co.uk/products/silencers/sn112-medium-duty-absorptiv.pdf

6 Pneumatic Nozzle Noise Reduction

Another common feature of many sites is the use of “nozzles” that are simply open ended pipes run at full factory line pressure, whatever the application.

Typical applications

Cooling, drying, blowing, cleaning, component ejection…

Benefits

Low noise and much reduced compressed air use for the same duty, intrinsically safer. A widely applicable reduced energy noise control technique.

Technique

In most cases, it is possible to exchange existing nozzles (usually simple copper pipe tube outlets) for quiet, high efficiency entraining air nozzles. These will not only often reduce noise levels by 10dB(A) (or more), but they also use less compressed air (typically 20% less) for the same performance. Consequently, they pay for themselves quite quickly.

Also consider reducing the airline pressures wherever possible, running tests to determine the minimum pressure required for the job. This not only reduces the noise further, but it also reduces air consumption.

The generic types of nozzle to look out for are entraining units (see schematic and photograph) from various manufacturers. These accelerate ambient air to provide less turbulent mixing – which means less noise – and are available in a variety of sizes. As the outlet cannot be blocked with, for example, a finger, they are intrinsically safer than a copper tube outlet.

Limitations

Occasionally, space and performance requirements mean it is not practical to use an entraining nozzle.

Examples

Standard camshaft washer drying nozzles were replaced with suitable high efficiency entraining units after performance testing. These not only reduced the noise at source by 12dB(A), but they also reduced the drying cycle time by around 20% and reduced the air consumption by a similar percentage.

Hand-held non-entraining nozzles used for cleaning and drying can always be replaced with entraining equivalents that reduce noise levels, improve safety and reduce air consumption (win-win-win). The same goes for vibratory bowl feeders and conveyors that use air to aid component movement.

Even high performance nozzles used, for example, in power press component ejection, can usually be replaced directly with entraining nozzles to provide a 10dB noise reduction (and a saving on compressed air) without compromising the speed of ejection.

Air lance nozzle change video example at https://youtu.be/9yzqaMHlvJ0

Download the Top 10 noise controls pdf with sound files here >

Suppliers: ranges of high efficiency nozzles are available from:-

https://www.brauer.co.uk/airmiser-nozzles-s149.aspx

http://www.silvent.com/en-uk/products/

7 Chain Drives and Timing Belts

Chain rattle (particularly on guides as the chain wears) and the banshee tonal wail of timing belts are not uncommon noise sources that can often be reduced at source quite easily.

Technique

Noisy chain drives can often be replaced directly with quieter timing belts. Within the range of timing belts available, there are quiet designs that use modified tooth profiles and pulley geometries to minimise noise. For applications where noise is critical, there are chevron (or helical) tooth patterned belts that can provide very quiet running. Noise reductions in the range of 6 - 20 dB(A) are often practical via this approach.

The noise from timing belts is also very sensitive to the correct belt tension. If the belts are over-tightened, the noise increases dramatically (5 – 10dB). Ensure that maintenance engineers know the correct tension – and make it easy for them to adjust the tension to the correct value. This also extends belt life.

The noise from chain drives can also sometimes be reduced by fitting laminated steel guides (the same material as recommended above for vibration damping) at key positions to smooth the path of the chain.

Typical Applications

Noisy chain or belt drives and conveyors.

Benefits

Reduced noise and wear rates.

Limitations

It is not always practical to implement the quieter options (space, power transmitted, temperature…).

Suppliers: low noise toothed belts are available from:-

http://www.cross-morse.co.uk/timing_belt2.asp

http://www.transdev.co.uk/pages/belts/eagle/eaglepd_advantages.htm

Most of the major suppliers have quieter versions of their drives, usually associated with higher quality and performance products.

Download the Top 10 noise controls pdf with sound files here >

8 Electric Motor Noise

Most companies have large numbers of electric motors across a wide range of applications.

Technique

Some electric motors can be very noisy (>90dB(A) at 1m), particularly higher speed (2950rpm) units. However, it is not necessarily common knowledge that general duty motors are available (at little or no cost premium) that are up to 10 dB(A) or more quieter than typical units as direct replacements. The best approach is to feed these motors into the purchasing system over a period of time so that all replacement motors are quiet motors.

In many cases, the quieter motors are also more efficient units which means that the running costs are also reduced.

Typical applications

Noisy motor drives – pumps, gearboxes, fans etc…

Benefits

Lower noise levels with no effect on performance.

Limitations

This approach can take significant time (and some capital) to implement if the motors are replaced gradually – although more rapid implementation is possible where the new units reduce running costs.

However, we also have a standard modification design that can be retro-fitted to existing motors that typically reduces the noise by c 10dB(A). Contact us for more information.

Download the Top 10 noise controls pdf with sound files here >

9 Hydraulic Power Pack Noise Control

Hydraulic power pack noise is a common problem as they often seem to have been specifically designed to be as noisy as possible... The classic example is a hydraulic motor-pump unit that is not intrinsically noisy when suspended in free space, but is then bolted to a large sounding-board in the form of an oil tank that behaves as a very efficient loudspeaker. The conventional acoustic enclosures sometimes used cause both thermal and maintenance problems (small leaks go unnoticed). However, the noise from most hydraulic power packs can be dramatically reduced using low-cost engineering techniques that have no effect on temperature or access.

Typical Applications

Hydraulic power packs that include oil tanks, submerged pumps or pumps bolted to large steel structures.

Benefits

No enclosure (thermal and maintenance problems), large noise reductions at low cost.

Hydraulic power pack noise reduction techniques

The problem is that the vibration source (hydraulic pump) is rigidly connected to a large radiating surface that amplifies the sound. The simplest solution is to install a vibration break between the hydraulic pump (or the motor-pump unit) and the tank. This can be achieved by fitting a carefully designed vibration isolation pad (e.g. rubber-bonded cork – see section 2 above) between the pump and the tank and by ensuring that there are no rigid connections i.e. fit flexible hydraulic hoses and ensure that the heads of the bolts are also isolated as shown in section 2. This reduces the classic high-frequency tonal noise from these units. Note that it may also be necessary to isolate valve blocks in a similar manner.

Where the motor-pump alignment could be an issue, then it may be necessary to construct a simple steel frame (angle iron) to which both motor and pump are bolted to maintain alignment and then isolate the combined structure from the tank. In addition, if there is any residual high-frequency vibration radiated by the tank or associated steel mounting panels for control systems, it can be damped by creating a laminate in situ (as per vibration damping in section 1 above).

Noise reductions of 10dB – 20dB can often be achieved using this approach at low cost and without affecting temperature, access or visibility (potential oil leaks). Example of hydraulic power pack noise control using vibration isolation and damping >

Limitations

Few as this approach almost invariably provides an elegant engineering solution to a common noise problem.

Download the Top 10 noise controls pdf with sound files here >

10 Convert Existing Guards into Acoustic Guards

Provided the noise from a machine is dominated by airborne components, existing safety guards can often be converted into effective acoustic screens. If a component of the noise is vibration radiated as noise, then the guards can be damped (as section 1 above).

Typical Applications

Machine tools, power and printing presses, packing and filling machines, conveyors etc etc…

Benefits

Simple and low-cost upgrade to reduce noise levels.

Technique

The existing guards on many machines can often be simply improved to provide a significant noise reduction. The two key principles involved are:-

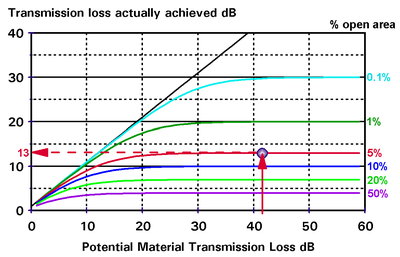

i) Minimise gaps: halving the open area (“gaps”) in a set of guards will reduce the noise by c 3dB. If you can reduce the openings (flexible seals, additional close fitting panels etc) by 90%, then a 10 dB noise reduction is possible. The graph above shows the trade-off between open area and attenuation. If the guard is made from steel with a theoretical attenuation of 42dB (see example shown on graph), looking up the actual attenuation achieved in practice with a total gap or leak of 5% (for the guard) gives a figure of 13dB i.e. the maximum attenuation will be 13dB. If you reduce the total gap to 1%, then the attenuation increases to 20dB.

In practice, the modifications can range from covering the whole of a mesh guard with steel or polycarbonate sheet, fitting a “roof” over simple vertical guards or blocking relatively small leaks round the edges of quite close fitting guards with seals or rebates.

ii) Acoustic absorbent: lining a significant proportion of the inside of the guards with acoustic absorbent (foam, rockwool / fibreglass, sealed hygienic absorbent modules) will reduce the reverberant noise “trapped” by the guards. Consequently, the noise level inside the guards will fall and therefore less noise will escape through any gaps. There is no necessity to cover the whole of any panels, just fit patches of absorbent on convenient flat surfaces or even hang small absorbent panels inside the volume.

In cases where hygiene is an issue, there are high hygiene sealed absorbent materials available such as Hygiene Advance A from:-

Ecophon: +44 (0) 1256 850977

http://www.ecophon.com/uk/products/Modular-ceilings/Hygiene/Hygiene-Advance--A-C3/

Custom Audio Designs

http://www.customaudiodesigns.co.uk/

"Blue Peter" Testing

In most cases, both sets of modifications can be tested in mock-up form using cardboard (and wide tape) to cover gaps or to extend the guarding. You can then fit areas of acoustic foam inside the guards to test the results (taking care to account for the background noise from other sources).

Not only does this process help with the practical aspects (assessing the potential effects on access, visibility etc), but it usually also provides a very good indication of the noise reduction that can be expected in practice.

Note that you can cover open guards (mesh etc) with polycarbonate sheet if visibility is required. This may seem a very “Blue Peter” exercise, but it is a quick and effective way to assess the acoustic performance of the options before spending money on the final version made from steel, aluminium, polycarbonate or even plywood. Remember that guard vibration radiated as noise can also be treated via damping (as section 1 above).

Limitations

The law of diminishing returns sets in once you have closed the largest gaps and leaks, so there is a limit to the attenuation that can be achieved. Visibility can also be an issue that limits the area of acoustic absorbent that can be included inside guards. However, we have developed and used a few innovations for this type of application – contact us to discuss particular issues.

Download the Top 10 noise controls pdf with sound files here >

Further Information and Resources

Technical support for all these techniques and further case studies are available from us. Feel free to contact us or call to discuss particular applications.

For more extensive noise problems across departments or whole sites – the next step is to...

Plug-in to our noise control expertise

The noise control diagnostic process detailed above must always be followed to evaluate what constitutes best practice. The basic process does not require a high level of engineering skill, but you can also plug-in to our expertise to update a noise risk assessment with the noise control element or evaluate the options for a noisy machine.

We have a very extensive noise control best practice knowledgebase that can be accessed by email (Remote Control of Noise - send us noise data, photos and smartphone recordings) or we can carry out noise control audits following the procedure shown here to provide a state-of-the-art cost/benefit analysis.

You can also download the Top 10 noise controls pdf with sound here >

Your problem may already be solved

Search our worldwide best practice options

Remote Diagnosis

Email us a video from your smartphone for free evaluation of best practice