Cut Product Noise and Vibration – innovative and profitable

We are extremely successful at applying engineering experience, intuition and technology transfer across many industries to eliminate product noise and vibration problems. Our clients benefit commercially and technically from this success. Innovation, innovation, innovation…

For experienced engineers, solving noise and vibration problems is as much an art as a science – we provide both to help with your product development. Our reputation for successful innovation is illustrated by the range of novel and elegant engineering solutions contained in our case studies.

Commercial Benefits - Buy Quiet

- Would you gain a commercial advantage if your products are much quieter and smoother than your competitors?

- Would you benefit if your noise and vibration controls cost a fraction of those in competing units with no effect on performance, access, maintenance, cleaning or efficiency (unlike conventional techniques)?

Incorporating our technology increases product profit margins - plus in some instances, retrofit noise control kits have been sold very profitably to reduce existing plant noise.

Free Remote Diagnosis

Email us a video from your smartphone for an evaluation of best practice

Your problem may already be solved

Search our worldwide best practice options

Sample Past Project Areas Include...

Dust control fan noise

We helped a company develop the quietest and most efficient dust control fan on the planet. Our noise attenuation design changes made the new fan model:

- 98% quieter

- 17% increased performance and with reduced power consumption

Air-source heat pump noise reduction

Our recommendations resulted in:

- 90% reduction in overall noise

- 15dB tonal noise attenuation with no effect on system performance or efficiency

Profitable noise control is no longer an oxymoron...

Other project areas include:-

- Air conditioning

- Axles

- Office products

- Pneumatic nozzles

- Trains

- Compressors

- Power presses

- Weighing Machines

- Ships and yachts

- Steering columns

- Vibratory filters

- White goods

- Pneumatic tools

- Woodworking machines

- Fans

- Wrapping machines

- Vacuum cleaners

- Vacuum pumps

Dust control fan noise can be both an occupational noise hazard and the cause of environmental noise complaints. The fan manufacturer approached us to see if our aerodynamic fan noise control technology could offer a more elegant engineering solution to reduce fan noise rather than resorting to crude and costly mufflers.

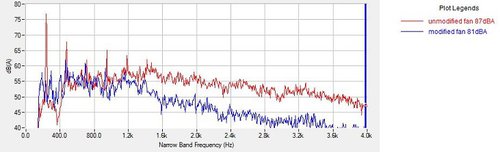

We designed fan modifications that combined the results of CFD computer modelling and aerodynamic fan noise attenuation technology. These not only dramatically reduced the fan noise, but also provided a substantial boost to the performance and efficiency (as shown here) - all at a zero implementation cost. Contrast this result with the reduced efficiency and increased costs associated with conventional silencing. As the aerodynamic features are designed-in, there are also no maintenance or additional manufacturing costs compared with standard fans.

The new high-performance fan represents a major advance in the dust control fan system technology, combining low noise with very high performance and increased efficiency.

Dust control fan noise reduction and efficiency gains - the figures

The key performance figures for the fan modifications are:-

- Tonal noise reduction: 98% (17dB)

- Noise reduction at 10’: 75% (6dB(A) down to 81dB(A))

- Power consumption: 6.6% reduction

- Pressure head: 16% increase

- Airflow: 7.8% increase

- Air velocity at 40’: 17.3% increase

This noise analysis plot shows both the overall dB(A) noise reduction and the dramatic cut in the annoying blade pass frequency tone (hum) generated by the fan.

Noise reduction tech that generates a substantial commercial benefit

Whilst this project began as a noise attenuation exercise to satisfy customer requests for quieter units, the result of applying our innovative expertise in fan noise control was the quietest and most efficient dust control fan available - at no additional manufacturing cost.

Profitable noise control is no longer an oxymoron...

The manufacturer of air-source heat pumps approached us to use our diagnostic skills and technology help them to reduce the noise from their units without recourse to expensive, efficiency-sapping enclosures and silencers. The objective was to design-in low-cost engineering noise control features to make the units inherently quieter - without compromising efficiency.

Heat pump noise diagnosis

The diagnostic analysis showed that there were 4 major noise sources, all of which would need to be reduced in order to achieve the desired noise reduction. The sources identified were:-

- fan: tones at 70Hz + harmonic - cannot be reduced using silencers or barriers

- mains hum: 100Hz tone

- compressor: several tones

- air noise: broadband sound

Previous resources had been focused on reducing the overall dB(A). However, the low-frequency tones were the dominant noise complaint issue despite only contributing <0.5dB to the overall dB(A). These would not have been reduced by the conventional methods under consideration.

Noise-reducing modifications

These involved the following:-

- fan tones: aerodynamic modifications

- mains hum + compressor: high-performance damping of key components + local tuned acoustic absorbent

- broadband air noise: once the low-frequency components had been cut, a simple small carefully designed screen was very effective

The combined effect was to reduce the 70Hz fan tone by 97% (15dB) and the overall noise by 90% (10dB(A)) without affecting the efficiency of the heat pump as demonstrated by the above analysis and the sound file.

View a more detailed guide to heat pump noise reduction covering both air-source and ground-source noise control.

As part of a continuous product development programme to maintain their world-leading reputation, CompAir asked us whether it would be feasible to re-design the noise control package on one of their compressors. The initial target was to remove the existing silencer element to reduce the overall size of the unit – without any increase in noise or a reduction in the performance of the cooling system.

Source control modifications were developed for the cooling system which significantly reduced the overall noise from this element at source and also dramatically cut the tonal content (less “nuisance”). Coupled with modest flow and geometry changes, the new package reduced the overall “headline” noise from the compressor by 2 – 3dB(A), despite removing the standard silencer – and all without any cost or performance implications.

Variable Frequency (VFD) drive cooling fan noise is often the major source from these systems. Reducing this element of the noise is a non-trivial project given the space limitations and the fact that cooling efficiency must not be affected.

Reviewing the noise attenuation options for their product range led a major VFD drive manufacturer to approach us to help them to design noise attenuation modifications for the cooling system based on our aerodynamic technology. They could then use the technology across the entire product range.

The whole project was carried out remotely via internet, saving time, money and carbon.

How to reduce VFD drive noise - the cooling fan

The low-noise product design process is outlined below.

- Provide a detailed set of baseline measurements and procedures

- Create a Computation Fluid Dynamics (CFD) model of the fan

- Design the aerodynamic modifications

- Test the results and copy the design across the product range

VFD noise reduction - the result...

Our final low-cost design modifications cut the annoying fan tone by 99.5% (23dB) and the overall noise by 50% whilst simultaneously increasing the airflow by 3%, ready to be copied across the entire product range.

The key to the successful noise attenuation was to combine aerodynamic expertise with CFD modeling in order to optimise fan efficiency whilst, at the same time, eliminating the annoying fan blade pass tone.

The top figure shows the velocity output from the CFD model for the standard fan. 3 iterations of design and simple testing resulted in modifications to alter the flow through the fan as illustrated in the second picture that reduced the blade pass tone by 23dB in parallel with increased airflow.

Fan noise reduction in product design

This approach is ideally suited to improve the noise profiles of products that include fans. Our aerodynamic fan noise control technology often makes it possible to cut noise at little or no increased product cost and with increased fan efficiency - neither of which applies to conventional silencers. Our current record holder is a dust control fan noise reduction project: 17dB tonal noise attenuation with over 20% improved performance...

During the re-design exercise for a new model, the noise from this vacuum cleaner was not only reduced by a factor of 10 (10dB(A)), but the subjective character of the noise was also substantially changed by eliminating tonal components to make it sound “nicer” (a specialist technical term in acoustics!). The development process involved very detailed diagnostic analyses to rank the contributions from all the noise sources so that the optimum modifications could be designed. Consequently, the cost in the final new product of the designed-in noise reduction features was negligible.

The noise reduction programme result also had the side effect of making the vacuum cleaner sound more powerful…

The noise from the Eurostar Nightstock HVAC module (140 had been built) was unacceptable in terms of overall noise and tonal content at the fan blade pass frequency. Conventional noise control techniques (silencers) from the manufacturer had been unsuccessful.

Maintaining the fan performance was critical and space within the air conditioning system was severely limited and a retro-fit solution was needed very quickly. The optimum solution involved a combination of Quiet Fan technology with a new 7 bladed impeller design that could be fitted very quickly at low cost and entirely within the existing HVAC unit i.e. no space implications. This reduced the annoying blade pass tone by 24dB and the overall system noise by 8dB(A).

As the fan noise reduction modifications reduced the noise at source, they simultaneously treated the intake, exhaust and break-out noise through the fan casing. Conventionally you would have needed separate attenuators for each transmission path that would have had a catastrophic effect on HVAC system performance.

The whole project was completed within a few days.

There is enormous competitive pressure on suppliers to develop quieter HVAC and chiller plant. We’ve applied our engineering skills to design-in engineering noise control modifications for a new range of A/C units. As a result, the manufacturer can now quote sound power levels that are at least 4dB(A) lower than before, at, quite literally, no additional cost to the units whatsoever and with no effect on system efficiency. Moreover, the project was completed within a few weeks.

This has provided the company with a significant commercial advantage and illustrates the benefits of introducing engineering noise control techniques during the development of new products. Quoting the project manager:-

“.. is the unit actually running?! .. That’s an amazing result over such a short timescale”.

Extensive and very detailed diagnosis and analysis techniques led to the devlopment of an engineering noise control at source kit for this Molins making machine. It reduced the noise by 4dB(A) at very low cost and without affecting normal access or operation (unlike previous suggestions involving acoustic screens) which was sufficient to avoid mandatory hearing protection.

It was licensed by the manufacturer so that they could provide a very profitable retro-fit or overhaul option service worldwide. This illustrates the commercial opportunities inherent in the engineering noise & vibration control technology in which we specialise.

Vibratory separator, screen or sieve noise is traditionally difficult to reduce as it is often predominantly a low-frequency issue. However, we have developed a range of elegant, low-cost engineering solutions that have wide application are are ideal for both as retrofit to existing units or that can be designed-into products at virtually no cost.

In this case, vibration was fed into the product via the separator drive and there are structural components that radiate noise. The trick is to ensure that as much of the "working" vibration as possible is fed into the product and that the spread of extraneous higher-frequency vibration is minimised.

We developed engineering source control techniques for the manufacturer of a range of vibratory separators, screens and sieves that could be built-in to their products without affecting access, maintenance or normal operation. These reduced the vibrating screen noise by 5dB - 12dB(A) at source at very low cost and without compromising hygiene or machine performance.

In this example, the noise control features included adding a high level of constrained layer damping to the sieve body itself and developing a spun laminated steel bowl to reduce impact noise.

This approach can also be used to develop low-cost engineering retrofit modifications for vibrating sieve or separator noise reduction.

Contact us if you'd like to discuss a particular project.

We have also generated a comprehensive technical note on all aspects of vibrating bowl feeder, hopper, conveyor and screen noise...

Other examples of our engineering vibratory system noise reduction technology include:-

This suction fan used in a newly designed, automated pick-and-place system for food packets on a production line generated high levels of noise. Conventional fan silencing would not only have posed a hygiene problem (attenuators make use of porous acoustic absorbent materials), but would also have required acoustic enclosure.

We re-designed the fan mounting system (interestingly, the fan itself was designed for model aircraft engines) and modified the geometry slightly. This reduced the fan noise at source by 8dB(A) without affecting the efficiency of operation - and at zero cost once designed-in to the unit.

Weighing machines for the confectionery industry are a very common noise problem. In this case, the purchaser had implemented our Buy Quiet policy for new plant, with a target of 75dB(A) for this particular installation. One of our engineers attended the new machine proving trials at Easiweigh as part of the purchasing policy process to determine what would constitute best practice to meet the noise specification. We developed a set of modifications that reduced the initial 83dB(A) Leq noise level down to the required 75dBLAeq.

The low cost, high hygiene modifications included replacing the conventional (and non-hygienic) damping materials with much higher performance stainless constrained layer damping. This has since been adopted as standard practice on all new weighing machines.

We were asked to look at improving the acoustic design of Custom Design speaker stands for up-market Hi-Fi aficionados. As a result of vibration testing on the stands, we recommended replacing the top and bottom plates with laminated “dead-metal” versions. These reduced the vibration response of the stands by up to 40dB (a factor of x100). According to the review in Hi-Fi Choice:-

” .. switch to the acoustic steel plates and the sound is even better, with a deeper, quicker bass and a more open mid-band. There’s definitely a neutralising effect with the acoustic steel that zaps a lot of colouration, giving a far more neutral sound … Top value upgrade .. 5 stars.”

The purchaser of several multi-spindle auto lathes was on the point of cancelling the order as the first completed machines did not meet the agreed noise level of 83 dB(A) (3000 rpm) – they were typically generating 87 – 90 dB(A). We used the results of sophisticated noise and vibration analysis to recommend a change in the assembly procedures used that reduced noise levels to <83dB(A) at negligible cost.

The diagnosis and recommendations were completed in less than 2 days and, as a result, all purchasers now receive quiet machines. This illustrates the benefits of effective policing of purchasing requirements.

A major customer implemented our Buy Quiet purchasing policy and passed-on to the supplier a request to reduce the operator noise levels from 90dB(A) down to below 85dB(A) in the production environment. We were retained by the manufacturer to provide design improvements as part of the of the machine development programme. Our engineering recommendations reduced the machine noise down to 82dB(A) at a cost of around £300 per machine (c 2% of the capital cost) without affecting normal operation or access. Modifications included sewing machine damping, control of exhaust air and minor changes to the machine base.

Your problem may already be solved

Search our worldwide best practice options

Free Remote Diagnosis

Email us a video from your smartphone for an evaluation of best practice