Chiller, cooler AHU noise control techniques

Chillers, dry and adiabatic coolers and air condensers are very common sources of environmental noise problems. Fortunately, there are elegant, low-cost retrofit engineering solutions that do not reduce efficiency. Unfortunately, installing ineffective noise control measures that are costly and seriously reduce system efficiency is also common. There is a simple process to determine the best noise attenuation method that is also generally applicable to all air handling unit (AHU) systems. Chiller/cooler, and similar heat pump noise control must be based on understanding the 3 typical noise sources, each with its own characteristics and each with a different optimum silencing solution.

What are the features of AHU noise?

AHU fan noise comes in 2 distinct flavours:

- mid-high frequency air noise: silencers and barriers can work well, but can also reduce efficiency (depending on geometry)

- chiller fan hum: very low-frequency tones: use aerodynamic fan noise control technology that can increase fan efficiency by 10% - 20%: silencers and barriers are ineffective at these low frequencies

In addition to the AHU noise components, there may also be very characteristic compressor noise

- compressor whine: low-frequency tones plus harmonics - use engineering source control first as other techniques can reduce performance

Not using the diagnostic process described below cost one company over £100k. They replaced an air conditioning chiller AHU based on an assessment of the overall dB(A). In fact, the complaints were caused by a different unit generating a low-frequency hum from the fan...

Sound file: dry chiller and AHU noise control at source: 12dB(A) attenuation

Broadband mid-high frequency air noise

Caused by AHU fan-generated air movement that usually dominates the overall dB(A) noise level. By their nature, air-cooled condensing units, air handling units, adiabatic coolers, heat exchangers and air conditioning plant pass high volumes of air through heat exchanger radiators. The airflow through less-than-ideal paths generates turbulence and therefore sound. This type of noise is reasonably directional and can be attenuated by conventional silencers and acoustic barriers. However, great care must be taken to avoid reducing the efficiency of the AHU or chiller:-

- AHU inlet and exhaust silencers: can generate high backpressures that either cut airflow (reducing cooling) or that require higher fan speeds, increasing noise and power consumption. Bespoke silencer design can be an option to minimise these effects

- noise barriers: these have to be placed as close to the chiller as possible for maximum attenuation. This reduces airflow and free-cooling, compromising efficiency. Careful location and geometry design can minimise these losses, as can taking advantage of the physics of directional sound. We have developed a unique broadband barrier noise control system that provides high attenuation without reducing efficiency.

Chiller noise control examples

Free Remote Diagnosis

Email us a video from your smartphone for an evaluation of best practice

Chiller compressor noise control (whine or hum)

Compressor hum is caused by pulsation vibration transmitted into the structure that is then radiated as sound or via direct vibration from badly mounted units. You typically get tonal noise at the rotation speed (usually c 49Hz) and many harmonics over a wide frequency range. Particular high-level tones occur at the pumping frequency from pipework pulsations as shown here. Anyone can easily diagnose this issue using one of the many free spectrum analyser apps on a smartphone. The most effective chiller compressor noise reduction options involve the following:-

- vibration isolation

- vibration damping

Once these have been addressed, then enclosure and/or barriers can be added if necessary. Note that enclosing without considering isolation and damping is often completely ineffective.

Vibration isolation: you cannot use sound as the diagnostic tool due to complex reflections of tones. You must use vibration measurements to determine the transmission paths. However, it is often possible to evaluate common issues by inspection. Is the compressor vibration isolated effectively (not hard mounted, are there any vibration breaks in the pipework, no short-circuits, not mounted off thin panels)? How is the high vibration pipework attached to the frame?

Vibration damping: compressor and pipework vibration are fed into the chiller frame and thin sheet metal panels that then behave as efficient loudspeakers. The simplest (and low cost) solution is to introduce high-efficiency damping to the radiating surfaces to dissipate vibration energy to reduce the noise. This can be applied either by replacing thin panels with laminated versions or by retro-fitting high loss damping in situ e.g. https://sounddampedsteel.com/laminated-metal-how-does-it-work/.

If the compressor is the dominant source, these engineering source control techniques can reduce chiller noise by 5dB - 15dB.

Chiller, cooler, AHU fan noise attenuation (hum)

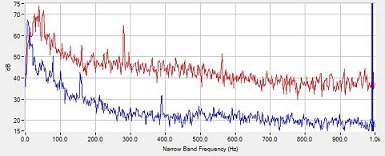

The hum often associated with chiller condenser fans (a very common cause of complaints) is often at a very low frequency at the blade pass frequency of the fans (speed x number of blades) caused by poor aerodynamic flow through the impellers. One of the most common and costly mistakes involves wasting resources on silencers and acoustic barriers in an attempt to deal with the hum. Neither is effective at these low frequencies, typically in the range 40Hz - 200Hz as shown here. Also note that these low-frequency AHU noise tones do not contribute significantly to the overall "A" weighted noise level (the "A" in dB(A)). Not understanding this simple fact is a very common source of very costly mistakes.

Once again, this source is easily diagnosed using one of the many free smartphone spectrum analyser apps - no sophisticated instrumentation is needed to avoid the costly mistake of assuming silencers or barriers will work.

The only effective solution to reduce low-frequency tonal AHU fan noise is either to buy new low-noise units or to fit low-cost aerodynamic fan modifications to reduce the tones. The latter are retrofit inserts and geometric flow control devices we have developed that eliminate the pressure fluctuations causing the hum at source by up to 99% (20dB) or more. This is a very low-cost solution that can also improve fan efficiency - by as much as 23% on one data centre relief fan application. This often makes these noise control projects self-financing.

Chiller / cooler / AHU noise control: the process

We follow this simple procedure to ensure that the optimum environmental noise control package is applied. You should always do the same. This approach applies to all chiller, AHU, dry cooler, air condenser, HVAC and refrigeration system noise problems.

- Analyse the problem: use a free smartphone frequency analysis app to assess tonal content - or email smartphone noise or video recordings to us for a free analysis

- Diagnose the source(s): link tones to chiller components as detailed above

- Source control: select the appropriate noise control measures (as above) for the problem source(s)

- Check noise attenuation performance: reanalyse frequency content and noise levels

Unless this process has been followed, then the selection of, and expenditure on noise control measures has been based on guesswork - which can be very costly.

We provide the whole process as a turnkey service, usually without a site visit via remote control of noise. The initial analysis and diagnosis are completely free - we provide you with the results and a detailed evaluation of the costed noise control options using current best practice. This can be followed by detailed recommendations for implementation by local contractors.

Chiller fan airflow efficiency modeling

In some cases, it is possible to improve fan efficiency significantly via the design of aerodynamic modifications. We use Computational Fluid Dynamic (CFD) modeling to visualise the airflow and use our very extensive past experience to design retrofit modifications. Improving efficiency not only reduces running costs, but as fans can be run at lower speeds, noise is also reduced.

West Group had installed a new HVAC system with 5 condenser units that caused noise complaints despite the headline dB(A) noise data suggesting there should not be a problem. They employed a noise consultant to devise a solution that was immediately implemented.

Ineffective HVAC silencers

Unfortunately, the silencers were completely ineffective as the consultants had failed to diagnose that the complaints were caused by a low-frequency hum and not by the overall dB(A) and, as a result of their (unfortunately all too common) incompetence, the Local Authority had to issue an abatement notice.

The company immediately stopped using the units but could not get a guarantee that the additional noise control measures suggested by the supplier would solve the problem. The EHO recommended that they contact INVC to consider alternative options.

Accurate noise complaint diagnosis

We diagnosed that the cause of the complaints was a low-frequency hum at the 53Hz – 57Hz blade pass frequency of the variable speed fans by analysing smartphone video clips and the audio recordings emailed by the EHO. The optimum solution was to design retrofit aerodynamic fan silencer modifications. These not only completely eliminated the problem tones (the major tone was reduced by 28dB) but also improved the system efficiency and the abatement notice was lifted.

The Facilities Manager, Bekki Jordan: “We sought expert advice on the noise problem as soon as it came to light, but unfortunately that advice proved to be both useless and costly. I want to take the opportunity to thank you for your help and support to allow us to get this ongoing issue resolved. The air conditioning has been running for two weeks now and we haven’t heard from either the council or the residents and the one resident who was spokesperson for the road said she can’t hear anything anymore…”

The whole project was carried out remotely, without a site visit, eliminating delays and travel costs.

New chillers installed on the roof of a university building were the cause of multiple noise complaints about the whine from the units. The proposals for the conventional acoustic enclosures, barriers and silencers were not only very high cost, but they would also have reduced the efficiency of the units, increasing running costs.

The university approached us for alternative chiller noise control options.

Chiller noise diagnosis and control

Narrow band frequency analysis showed that the cause of the complaints was a toothcomb of tones at the 246Hz compressor frequency and harmonics. This diagnosis proved that if these tones could be reduced, then the complaints would cease.

The conventional approach to chiller noise control is relatively crude in that the measures used do not address the sources of the noise, but simply treat the chiller as a noisy "black box" that has to be screened or enclosed. Our approach is precise: identify the source and use an engineering noise control scalpel to cut out just the problem noise components. This provides dramatically lower-cost solutions that have no effect on chiller efficiency.

In this case, a package of high-efficiency damping and local acoustic insulation was designed. Once installed, the tonal compressor noise was reduced by 10dB - 21dB (as shown here), eliminating further complaints.

Attempts are often made to solve classic low-frequency chiller AHU fan noise using conventional silencers and noise barriers. Despite the fact that there is zero chance that these techniques can work at low frequencies, a fortune is still wasted every year on these useless palliatives. As air handling units (AHUs) on industrial sites, offices, supermarkets and other retail premises are such a common noise problem that you would expect better solutions based on a better understanding of the issues.

AHU noise control failings...

Previous failed attempts on this air-cooled chiller (48.5Hz and harmonics) were replaced with aerodynamic techniques that reduced the tones by 95% and improved the fan efficiency – all by email via forwarded video clips and photos.

The company had already tried using a barrier to mitigate the noise complaints to no avail. This is because barriers are almost completely ineffective at frequencies below around 200Hz (heard as drones, hums etc). Chiller and AHU fans regularly generate low-frequency tones as the blade pass hum often falls in this range. Whilst acoustic barriers and attenuators can be used to reduce the overall dB(A) noise level, they do not touch the low-frequency tones that are very commonly the actual cause of complaints. Our analysis of emailed video clips can immediately confirm whether this is the case, avoiding potentially costly mistakes. In contrast, our aerodynamic axial fan noise reduction technology addresses the low-frequency noise problem by reducing it at source with increased fan efficiency as a common additional benefit.

What are the air handling unit noise sources?

Typically, there are only 3 sources/types of noise generated by AHUs. They are:-

- Broadband air noise ("rushing sound") from the fans across a wide range of frequencies. This dominates the headline dB(A) noise level and can be attenuated by conventional silencers, barriers and enclosures. However, these can significantly reduce the system efficiency, adding to the cost.

- Low-frequency tonal noise ("hum or drone") at the blade pass frequency of the fans. These do not usually contribute anything at all to the overall dB(A) figure - and yet are a very common cause of complaints. They cannot be attenuated significantly using conventional means, the only effective solution is to use low-cost aerodynamic technology, technology that will often increase fan efficiency, reducing the cost still further (self-financing).

- Mechanical noise due to vibration transmitted into the support structure and then radiated as sound. Tonal at the motor speed and higher harmonics. The best solution is usually very low-cost retrofit high-performance damping.

When considering the options to reduce air handling unit noise, it is vital to diagnose the precise nature of the noise problem and which source(s) are responsible to avoid wasting money on the wrong solution. For example, the solution recommended by consultants to cut complaints re noise from roof-mounted AHUs in London was to replace one of the units with a quieter model. This cut the noise on the roof by 7dB(A). However, the complaints continued as they were caused by low-frequency fan tones from a different unit.

The lack of a correct diagnosis cost that client over £100k...

Click this link for more detailed information on the best approach to noise attenuation for chiller, air condenser, HVAC and refrigeration fans.

Data centres (or "data centers" in the US) require a lot of cooling - which involves noisy chiller fans, air handling units (AHUs), cooling towers and condensers. Moreover, in addition to the general fan air noise, there are often low-frequency tonal elements (hums or drones) that cannot be silenced using conventional attenuators and acoustic enclosures and barriers. Unfortunately, poor diagnosis of the exact causes of noise complaints has often led to ineffective control of the noise from data centers that not only fail to solve the problem, but also compromise cooling efficiency.

Fortunately, there are effective low-cost alternatives that can actually increase cooling capacity...

Data centre noise problems - low-cost precision attenuation

A Noise Abatement Notice had been issued re the AHU noise from a large array of chillers at this data centre. The company had already spent nearly £100k on noise control with very little success and was considering claiming Best Practicable means (BPM) in court when the council suggested they might like to get a second opinion from us to avoid the legal route…

We carried out a very accurate diagnosis of the precise noise elements that were the cause of the complaints. Based on this evaluation, we designed a set of precise retrofit noise reduction measures that were guaranteed to be BPM. The innovative noise control measures included:

- Air handling units: changing the geometry of the AHUs and introducing internal modifications to convert existing elements into effective acoustic attenuators cut the broadband noise by >10dB(A) with no effect on fan efficiency

- Chiller condenser fans: the noise from these units was reduced by fitting a combination of high-efficiency damping coupled with internal and fan modifications, reducing the overall noise by around 8dB(A) with no effect on performance. Improvements were also made to the existing noise barriers.

These noise mitigation measures cut the overall noise at the complainants from 48.5dB(A) down to 36.5dB(A) (as illustrated by the audio recording above and by this noise signature) without affecting the performance of the cooling systems. In addition to the reduced broadband noise, the tonal "character" of the noise was also eliminated.

The whole process took approximately 6 weeks from start to finish and completely resolved the complaint issue.

Cost savings on noise control

The overall effect was to reduce the data centre cooling system noise by 15dB at less than half the previously expected cost. If this approach had been implemented in the first place, the company would have saved over £100k, the council would have saved resources and the complainants would not have had to suffer unnecessary disturbance over a 2 year period.

More details on how to reduce environmental noise from data centers

More on chiller, condenser and heat exchanger AHU fan noise reduction.

The cost of reducing the data centre noise from the air conditioning system chillers on the roof of a large multi-storey facility to meet the requirements of the Local Authority had been quoted as costing over £300,000 using conventional acoustic barriers and silencers. Fitting these acoustic screens round the chillers would have required:

- additional structural steelwork to cater for wind loading

- considerable planning (closing streets and bringing in cranes)

These proposed noise control measures would also have reduced the cooling capacity of the HVAC system, increasing running costs. The data centre communications company involved approached us in the hope that we might have a better idea.

We did...

Following very careful analysis of the noise sources and layout of the air conditioning plant and some lateral thinking, we designed an elegant solution involving a combination of:

- engineering control at source,

- innovative local acoustic treatments

- imaginative use of site geometry

- modifications to the chiller control system

The result was a set of modifications that were easy to implement in convenient stages and reduced the data centre AHU noise by 15dB(A) at a cost of c £40,000 – and with no effect on the normal operation or the overall efficiency of the system - unlike the previously proposed conventional noise barriers and silencers.

How to attenuate the noise from data centers

More details of the best approach to reducing the noise from chillers and air conditioning plant >

Chiller noise control costs were cut by 80% using new technology. The company running a server farm had spent £100,000 on noise control measures (acoustic barriers and silencers) for their HVAC and AHU plant to no avail – the complaints continued as the noise levels were virtually unchanged. We were invited by the Local Authority to provide both parties with a definitive statement as to what constituted “best practicable means” and to sort the problem.

Careful diagnosis allowed us to generate a best practice noise control package that would eliminate the problem at a cost of c £30k.

These measures included purpose designed silencing, geometry changes, improved acoustic screening and internal modifications to the main Air Handling Units. On the air conditioning condenser units, we by-passed the conventional solution of noise barriers and silencers as these are not only high cost control measures, but they can also reduce the efficiency of the chillers themselves. Our alternative was a set of low cost engineering noise control modifications that not only reduced the overall noise from the HVAC plant at source by 8dB(A), but also eliminated the hum (worth an additional 5dB(A) noise reduction with respect to environmental noise limits) – and with no effect at all on the chiller condenser performance or access.

The result was an overall noise reduction of 12dB(A) and the elimination of the tonal content of the noise from the condensers. If best practice had been used at the start, the company would have reduced the cost of the chiller plant noise control project by 70% and avoided several months of management hassle and a sacking…

The fans in this dry cooler were the cause of multiple complaints about a 97Hz low-frequency hum outside a sports facility. The owners could not find a supplier willing to guarantee the problem would be resolved using conventional enclosures and silencers.

Why silencers are not effective for low-frequency dry cooler fan noise

Conventional silencers do not work well at low frequencies - unless you can afford:

- a substantial reduction in fan efficiency that puts up power consumption and running costs

- space for, in this case, silencers that are around 6m long on both the intake and exhaust

- the budget for a large enclosure

At 97Hz the wavelength of sound is around 3.4m. You would need a conventional silencer approaching 2 wavelengths long to not cut the fan efficiency. Fan noise is also radiated equally through both the intake and the exhaust, so both paths would have to be silenced.

Using aerodynamic fan noise control instead of silencers

This innovative technology modifies the airflow through the fan to cut the low-frequency tonal fan noise at source whilst, in many cases, simultaneously increasing fan efficiency and hence reducing running costs. This raises the prospect that rather than being a cost, the noise control project could well be a profitable exercise.

As the attenuation technology cuts the noise at source, it reduces the sound from both the fan intake and exhaust simultaneously. In this case, as illustrated by the sound file and this frequency analysis plot, the low-frequency tonal hum harmonics from the fans were reduced by 90% - 95% (10dB - 15dB), eliminating the source of the complaints.

The whole project was carried out remotely using smartphone video clips and photographs (on another continent without a site visit), making it a very rapid and cost-effective process.

This alternative to conventional attenuators is much lower cost, dramatically more effective and is applicable to similar applications where axial fan noise is a problem such as on chillers and cooling towers.

Highly tonal noise from these chillers had been the cause of complaint for some considerable time. The company had already attempted acoustic enclosure with the result that the chillers had over-heated.

The EHO sent us sound recordings, photographs and noise levels. Once analysed, we were able to say that the noise problem could be resolved for a few hundred pounds without running the risk of chiller problems. Once this information was passed on to the garage, they contacted us and we supplied them with detailed drawings that they used to get the silencers made locally.

Problem solved…