Industrial fan noise reduction - no silencers, no maintenance, more efficient

How can you reduce the noise from industrial fans without impairing efficiency? Our self-financing fan silencing technology uses innovative aerodynamic noise reduction techniques instead of silencers. Installed in a multitude of fans and blowers across the planet, from 6cm diameter to 4MW behemoths, this technology has and is saving £millions in capital and reduced running costs.

Applicable to both centrifugal and axial flow fans (e.g. chillers), our muffler alternative can be retro-fitted in hours and is particularly effective at low-frequency fan hum noise reduction, providing both stealth and fan efficiency to eliminate complaints and to reduce energy consumption and carbon footprint compared with attenuators.

Magic? If this sounds "magical", read client comments and review the case studies.

“I have never seen such an amazing result from a consultant in my career.” View case study >>

Take advantage of our free email evaluation service to determine if you can use our technology in your fans (how Quiet Fan technology works). We provide instant diagnoses from smartphone data (Remote Control of Fan Noise - as used by environmental regulators and Env. Health organisations worldwide) followed by detailed solutions across the planet.

What causes fan noise and how can it be reduced?

Fan noise is caused by airborne aerodynamic turbulence (wasted energy). The key fan noise factors to consider for any project before specifying silencers are:-

- At optimum efficiency, fans generate least noise. Most silencers cause back pressure that cuts efficiency so the fan may have to be run faster - which increases the source noise (like running up a down escalator).

- Can the system be made more efficient? Small fan speed reductions = large noise reductions (variable speed drives).

- Can turbulence be reduced at source using aerodynamic inserts instead of attenuators that reduce efficiency and can clog?

- Is fan motor noise significant? If so, it can be reduced using engineering means rather than enclosure?

There are elegant engineering options to attenuate fan noise at a fraction of the cost of traditional techniques...

Fan noise reduced by 99% and costs by 80% using new technology

Award-winning fan noise control technology cut capital, installation and running costs by 80% compared with conventional silencers. Applying our noise reduction technology to three 4MW industrial fans at a Tata steel-works eliminated a long-running environmental fan blade hum noise problem and reduced the capital costs (>£800,000) and running costs (c £200k per annum) compared with attenuators.

It is equally applicable to chiller and data center cooling fans (where efficiency gains of up to 23% have been achieved) and to conventionally "difficult" applications such as fume extract and scrubber plant fans where conventional silencers cannot be used.

Applied more widely, the technology has the potential to contribute to a significant reduction in worldwide CO2 emissions.

Contact us to see if our technology is applicable to your fan noise problem. If it is, then in principle you could benefit from running a quiet fan in as little as a week from your first email not only at a small fraction of the cost but at reduced running costs due to higher fan efficiency compared with traditional attenuators and enclosures.

Free Remote Diagnosis

Email us a video from your smartphone for an evaluation of best practice

Your problem may already be solved

Search our worldwide best practice options

Keep current with best practice innovation

Subscribe for the latest in techniques and best practice

Quiet Fan Technology – industrial fan noise reduction without silencers

This high-efficiency industrial fan silencing technology reduces tonal noise (hum) at a fraction of the cost of traditional techniques such as silencers and enclosures. It achieves this noise reduction without the increased power consumption associated with conventional attenuators, lasts the lifetime of the fan without maintenance and can be retrofitted in a few hours.

Applications include extract fans, ID fans, data centres, chillers, air conditioning plant, fume extract and scrubber systems, process ventilation fans, cooling towers, HVAC, power stations, cement and steel works cyclone separators and most blowers where there are low-frequency or tonal noise issues.

View more information on tonal noise + how to use a free smartphone frequency analysis app to identify fan tones.

Industrial fan noise attenuation: how does the technology work?

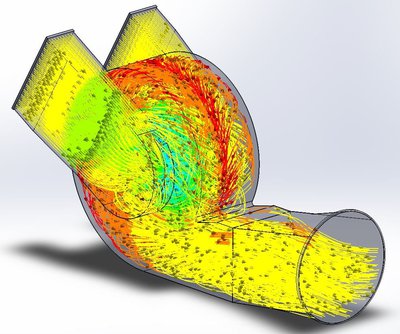

Originally developed for the Euro-fighter, we take a similar approach to Formula 1 teams who invest in aerodynamic aids to control airflow round cars. Fan noise is caused by pressure fluctuations shed by the impeller. We reduce these at source by designing aerodynamic (usually steel) inserts that fit inside the casing. This reduces the fan noise at source without the backpressure often associated with silencers.

Consequently, the fan noise is reduced without using costly silencers and, in some cases, with substantially improved fan efficiency (by up to 22% in one case).

As source control simultaneously reduces intake, exhaust and blower casing radiated noise, it may also eliminate the need for both attenuators and acoustic enclosures or lagging.

Fan noise attenuation: remote control anywhere on the planet

Fan or blower noise reduction problems can be solved anywhere on the planet via the internet - saving the time and money of site visits. The whole world now has instant access to this noise and energy-reducing technology. Successful projects across the globe include 5 large fans at this USA oil refinery where we reduced the noise reduction project capital cost from $1.25 million down to <$0.25 million…

Go to Remote Control of Fan Noise for case studies and details of the free smartphone email diagnostic service to diagnose if your project could benefit from this innovative technology.

Download "The Fundamentals of Fan Noise Control" guide here >>

Attenuators do not take kindly to the passage of scrap – which is a problem when installing noisy extract chopper (or cutter) fans. Our cutting-edge aerodynamic fan modifications, however, are even robust enough to be able to cope with the extreme case of the passage of scrap metal. In this example, both occupational and environmental noise problems were simultaneously solved at source.

Three sets of chopper fans are used to pull-off scrap aluminium cans from the production lines to shred them for recycling. These generated high levels of tonal noise (drone or whine), causing both occupational and environmental noise problems.

Instead of fitting conventional fan attenuators, acoustic enclosures and noise lagging at a potential cost of £30k or more, our Quiet Fan technology was fitted to the fans in a matter of hours to give an overall noise reduction of 22dB(A) at an installed cost of c £1000/line – a capital cost saving of 90% and with no effect on fan performance or efficiency.

Unlike silencers, the modifications are unaffected by the passage of scrap cans and will last the lifetime of the fans without maintenance – and at less than 1% of the previous noise level…

The same technique is widely applicable to all forms of chopper or cutter fans, not to mention for silence dust extract, cyclone and filter fans that process any form of waste material.

3 off, very large, 4-megawatt steelworks fans had been the cause of environmental noise issues for years. The problem was solved within months at a tiny fraction of the cost of attenuators by implementing our Quiet Fan technology aerodynamic fan noise reduction techniques. Fan power consumption was also reduced, making this a self-financing project.

We were awarded the annual Rushlight Noise Abatement Award for this project, an award that celebrates the organisations throughout UK and Ireland that have furthered environmental technology and innovation.

The fans generated a low-frequency hum (c173Hz) over a wide area. As the fan speeds varied, sophisticated resonator silencers were ruled-out and conventional attenuators would have imposed a very heavy penalty, not only in terms of capital and installation costs but also the increased running costs due to reduced fan efficiency. Tata approached us for a second opinion as to potential alternatives.

That second opinion saved more than a £million…

Our solution was to develop innovative retrofit aerodynamic modifications that were installed inside the fan casing, avoiding the need to modify either the existing ductwork or the stacks to fit silencers. This not only cut the capital cost dramatically but also reduced downtime from weeks to a weekend.

These modifications have eliminated the noise at source for the lifetime of the fans as they require no maintenance and have no effect on fan efficiency (unlike mufflers/attenuators).

The willingness of Tata to seek a second opinion reaped very substantial rewards compared with conventional silencing:-

- 94% + reduction in noise (12dB)

- capital cost savings of over £800,000

- substantial environmental benefits (carbon emissions)

- c £200,000 saved each year on running costs (power and carbon) compared with silencers

“INVC’s modifications have brought about a huge reduction in fan noise, improving the environmental conditions across a wide area around the Plant. They’ve also saved us a large amount of money by negating the requirement for major capital expenditure, so it’s been a remarkably successful project.” – Grahame Wallace, Tata

Fitting conventional silencers to this fan extract system seemed a long-winded and crude process to Red Bull who were used to the pace of change and the engineering innovation found in Formula One. Our approach was a perfect fit for their engineering ethos – 1000x less noise installed within a pit-stop of a few hours.

High speed fan noise reduction

Red Bull found an alternative to traditional attenuators in our Quiet Fan aerodynamic noise control technology. The aerodynamic inserts were designed, manufactured and installed inside the fan casing within a pit-stop window of just a few hours to dramatic effect.

The problem 218Hz low-frequency tone was reduced by a factor of around 1000... This reduction of 30dB set a new record for our innovative technology, completely eliminating the problem at the source for the lifetime of the fan, without maintenance and without affecting fan efficiency.

“We felt that there had to be a better way to reduce the fan noise other than by compromising the system efficiency and creating additional long term maintenance” said Terry Brice of Red Bull Technology.

“The INVC technique not only produced a fantastic result, but it’s also very satisfying as an elegant engineering solution”.

This low-cost source control technology is best practice for fan noise problems of this type, simultaneously cutting noise from the outlet, the inlet and breakout through the fan casing.

Despite considerable time and money being spent with the supplier and acoustic consultant installing silencers and reducing fan speed, a noise abatement notice was due because of numerous complaints about combustion fan noise. We resolved the problem overnight via Barry welding in 22dB of attenuation during a normal shutdown...

Combustion fan noise from a new waste heating system at a Palgrave Brown MDF site had caused numerous complaints from neighbours with a noise abatement notice in the offing. The fan system supplier and their consultants had tried conventional measures (additional silencing and reduced fan speed) over an extended period to no avail.

On the point of admitting defeat, they were referred to us by the local Environmental Health Officer. Our solution was to control the tonal fan noise at source using Quiet Fan technology aerodynamic fan noise control. This was fitted during a few hours of scheduled downtime. The next morning, it was hard to tell that the unit was running as the tonal noise from the ID fan had been reduced by 22dB and the overall level by 9dB(A).

A quick, low-cost and permanent attenuation for the lifetime of the fan without maintenance and without affecting efficiency.

The results were so impressive that the director, Alan Fillingham, recommended that our approach should be used throughout the group.

Compared with traditional attenuators or mufflers, this approach to induced draught (ID) fan noise reduction is not only typically 70% - 90% lower capital cost with significantly reduced running costs, but it is also much more effective at cutting the low-frequency tonal content that is a common cause of environmental noise complaints. It can also be used on fans that run at high temperatures.

Low frequency tonal noise (a 112Hz hum) from 8 very large architectural scale axial fans (several stories up that were already fitted with 8m long silencers!) at a Tata steelworks had caused environmental noise problems over a number of years. We diagnosed, we tweaked – and the problem was solved at virtually no cost…

All the possible conventional fan noise control solutions had been considered (largely additional silencers). These would not only have cost a large fortune (and would not have been effective at 112Hz), but they would also have reduced system efficiency and therefore increased the running costs.

Our detailed diagnosis revealed a system resonance that we addressed at source by slowing the fans very slightly. This reducing the fan tones by 20dB at virtually no cost, with no downtime and with no effect on the system efficiency.

A serious problem for the conventional silencing of quarry fan noise applications like this where the air is very dirty is the need to shut-down to clean the silencers on a regular basis with the associated cost implications. Our noise attenuating technology is immune to clogging, so no cleaning is needed - ever…

In this instance, the tonal noise (hum) from this quarry suction fan working under very dirty conditions was reduced by 23dB using our unique Quiet Fan technology. No silencers, no enclosure, no lagging, little down-time and no maintenance - ever (despite the operating conditions). Plus, this all comes at a tiny fraction of the capital cost of conventional silencing and without the associated running cost penalty.

This approach to fan noise reduction is particularly effective where the air is dirty as it avoids the need to clean silencers - plus it does not compromise fan efficiency. Consequently, it is the ideal noise attenuation method for dust and cyclone extract and filtration systems.

Paint spray booth extract fan noise control poses a problem for conventional silencing in that, even with effective filtration, the silencer will clog and lose attenuation. Moreover, paint fans often generate a low-frequency hum that passes through mufflers with little attenuation. This case study illustrates a low-cost alternative approach to spray booth extract noise reduction that lasts the lifetime of the fan without loss of performance.

A pair of classic industrial paint spray booth extract fan filter systems used on an MDF paint plant generated a very irritating low-frequency drone that was the subject of complaints both from operators inside the workshops and from local residents. At these low frequencies, conventional silencers would not only have been ineffective, but would have quickly clogged.

Moreover, as the pair of fans were not quite synchronised, the sound also had a distinctive “beat” which made it even more annoying. As the spray booth extract fan noise was at a low frequency of 146Hz, conventional silencers would have been very large, very expensive, would have required relocation of the plant and supplementation with lagging and enclosures (and regular cleaning). We bypassed all these issues by reducing the fan noise at source (Quiet Fan technology), eliminating the tones (13dB reduction) and the “beat ” with no down-time outside normal maintenance requirements.

This approach has a broad application for silencing paint plant, spray booth fans and other dust extract filtration systems as a more effective alternative to attenuators…

The Power Industry International journal published an article about the application of our innovative aerodynamic fan noise attenuation technology to cut not just the cost of noise control projects to reduce the noise from large fans feeding into stacks in the power industry, but also to improve fan efficiency.

The suggestion was that the widespread adoption of the technology could substantially reduce capital and running costs compared with traditional fan noise attenuation techniques such as attenuators, acoustic enclosures and lagging.

The journalist uses the application of the technology to the 50MW Schiller biomass power station in the US as an example. This is the largest power station of its type and uses a huge, house-sized ID combustion fan connected to a stack. The aerodynamic fan noise attenuation was installed within a time window of just 12 hours - compare that with the costly weeks of downtime required to install conventional mufflers. This cut the fan noise by 10dB at fraction of the cost and the fan efficiency was substantially improved.

An interesting point made in the article is that the noise control installation may seem too simple. The industry is used to the idea of massive noise control structures and extensive downtime. Compare that with the option to install elegant aerodynamic inserts inside the fan casing in a few hours to eliminate the noise problem at source without compromising fan efficiency.

Exactly the same point applies to many other industries such as steel and cement industry fans and the associated signature stacks that broadcast the fan noise far and wide.

Read the Power Engineering International fan noise control article

Cement fan stack noise reduced over a weekend...

Unfortunately, the plant update to improve the efficiency of the exhaust fans in a large cement works created a serious noise problem that generated complaints from miles around. A novel, low-cost attenuation system was designed and fitted over a weekend to avoid the eye-watering downtime cost required to implement conventional solutions.

Conventional stack silencing would have resulted in an unacceptable delay in solving the problem. In addition, it would also have involved massive capital expenditure plus the costs of a very prolonged shut-down and the system efficiency would also have been reduced. Our alternative solution was based on designing a set of bespoke stack silencer elements tuned to suit the noise signature. These were pre-fabricated off-site and then inserted into the stack through a small access door over a weekend.

The result was a 19dB noise reduction over the critical low-frequency range with zero effect on the fan or stack efficiency. The overall cost was a small fraction of conventional silencing - and without the reduced fan efficiency.

The alternative to costly 19th century attenuators

Large centrifugal cement works fans are a common source of low-frequency (and tonal) noise problems. Where the tonal content is the dominant issue, our aerodynamic fan noise reduction technology is by far the best alternative to fundamentally 19th-century noise control techniques such as silencers, enclosures and lagging. These involve high capital expenditure and extensive downtime to fit with increased maintenance and running costs (due to reduced system efficiency).

Where it is not possible to achieve the desired result using aerodynamics, this new stack modification technology can (and has been) been fitted in a couple of days to cut the noise across a wide range of frequencies without the reduction in fan efficiency often associated with silencers.

View the article published by the Global Cement magazine on this approach.

Severe noise problems were encountered from the fans in a new regenerative thermal oxidiser plant on an industrial site. The suppliers suggested an earth berm noise barrier, large fan silencers and acoustic enclosures that would not only have cost a 6 figure sum, but would have been a complete waste of money as they would not have worked as the problem noise emanated from the top of the stack.

We used precise diagnosis to isolate the key subjective sound features in addition to the overall broadband noise that dominated the dB(A). The optimum noise control modifications involved:-

- we removed the tones using our aerodynamic fan noise control technology

- one fan was slowed to remove the “beat” with the other unit

- the dampers were moved to improve flow

- small conventional attenuators were added to reduce broadband noise (as the low frequency elements had been removed, only small silencers were required).

These modifications eliminated all the noise character and reduced the overall noise by 15dB(A) at a few % of the costs associated with the proposed traditional (and largely ineffective) noise control package.

Data centres (or "data centers" in the US) require a lot of cooling - which involves noisy chiller fans, air handling units (AHUs), cooling towers and condensers. Moreover, in addition to the general fan air noise, there are often low-frequency tonal elements (hums or drones) that cannot be silenced using conventional attenuators and acoustic enclosures and barriers. Unfortunately, poor diagnosis of the exact causes of noise complaints has often led to ineffective control of the noise from data centers that not only fail to solve the problem, but also compromise cooling efficiency.

Fortunately, there are effective low-cost alternatives that can actually increase cooling capacity...

Data centre noise problems - low-cost precision attenuation

A Noise Abatement Notice had been issued re the AHU noise from a large array of chillers at this data centre. The company had already spent nearly £100k on noise control with very little success and was considering claiming Best Practicable means (BPM) in court when the council suggested they might like to get a second opinion from us to avoid the legal route…

We carried out a very accurate diagnosis of the precise noise elements that were the cause of the complaints. Based on this evaluation, we designed a set of precise retrofit noise reduction measures that were guaranteed to be BPM. The innovative noise control measures included:

- Air handling units: changing the geometry of the AHUs and introducing internal modifications to convert existing elements into effective acoustic attenuators cut the broadband noise by >10dB(A) with no effect on fan efficiency

- Chiller condenser fans: the noise from these units was reduced by fitting a combination of high-efficiency damping coupled with internal and fan modifications, reducing the overall noise by around 8dB(A) with no effect on performance. Improvements were also made to the existing noise barriers.

These noise mitigation measures cut the overall noise at the complainants from 48.5dB(A) down to 36.5dB(A) (as illustrated by the audio recording above and by this noise signature) without affecting the performance of the cooling systems. In addition to the reduced broadband noise, the tonal "character" of the noise was also eliminated.

The whole process took approximately 6 weeks from start to finish and completely resolved the complaint issue.

Cost savings on noise control

The overall effect was to reduce the data centre cooling system noise by 15dB at less than half the previously expected cost. If this approach had been implemented in the first place, the company would have saved over £100k, the council would have saved resources and the complainants would not have had to suffer unnecessary disturbance over a 2 year period.

More details on how to reduce environmental noise from data centers

More on chiller, condenser and heat exchanger AHU fan noise reduction.

Attempts are often made to solve classic low-frequency chiller AHU fan noise using conventional silencers and noise barriers. Despite the fact that there is zero chance that these techniques can work at low frequencies, a fortune is still wasted every year on these useless palliatives. As air handling units (AHUs) on industrial sites, offices, supermarkets and other retail premises are such a common noise problem that you would expect better solutions based on a better understanding of the issues.

AHU noise control failings...

Previous failed attempts on this air-cooled chiller (48.5Hz and harmonics) were replaced with aerodynamic techniques that reduced the tones by 95% and improved the fan efficiency – all by email via forwarded video clips and photos.

The company had already tried using a barrier to mitigate the noise complaints to no avail. This is because barriers are almost completely ineffective at frequencies below around 200Hz (heard as drones, hums etc). Chiller and AHU fans regularly generate low-frequency tones as the blade pass hum often falls in this range. Whilst acoustic barriers and attenuators can be used to reduce the overall dB(A) noise level, they do not touch the low-frequency tones that are very commonly the actual cause of complaints. Our analysis of emailed video clips can immediately confirm whether this is the case, avoiding potentially costly mistakes. In contrast, our aerodynamic axial fan noise reduction technology addresses the low-frequency noise problem by reducing it at source with increased fan efficiency as a common additional benefit.

What are the air handling unit noise sources?

Typically, there are only 3 sources/types of noise generated by AHUs. They are:-

- Broadband air noise ("rushing sound") from the fans across a wide range of frequencies. This dominates the headline dB(A) noise level and can be attenuated by conventional silencers, barriers and enclosures. However, these can significantly reduce the system efficiency, adding to the cost.

- Low-frequency tonal noise ("hum or drone") at the blade pass frequency of the fans. These do not usually contribute anything at all to the overall dB(A) figure - and yet are a very common cause of complaints. They cannot be attenuated significantly using conventional means, the only effective solution is to use low-cost aerodynamic technology, technology that will often increase fan efficiency, reducing the cost still further (self-financing).

- Mechanical noise due to vibration transmitted into the support structure and then radiated as sound. Tonal at the motor speed and higher harmonics. The best solution is usually very low-cost retrofit high-performance damping.

When considering the options to reduce air handling unit noise, it is vital to diagnose the precise nature of the noise problem and which source(s) are responsible to avoid wasting money on the wrong solution. For example, the solution recommended by consultants to cut complaints re noise from roof-mounted AHUs in London was to replace one of the units with a quieter model. This cut the noise on the roof by 7dB(A). However, the complaints continued as they were caused by low-frequency fan tones from a different unit.

The lack of a correct diagnosis cost that client over £100k...

Click this link for more detailed information on the best approach to noise attenuation for chiller, air condenser, HVAC and refrigeration fans.

The cost of reducing the data centre noise from the air conditioning system chillers on the roof of a large multi-storey facility to meet the requirements of the Local Authority had been quoted as costing over £300,000 using conventional acoustic barriers and silencers. Fitting these acoustic screens round the chillers would have required:

- additional structural steelwork to cater for wind loading

- considerable planning (closing streets and bringing in cranes)

These proposed noise control measures would also have reduced the cooling capacity of the HVAC system, increasing running costs. The data centre communications company involved approached us in the hope that we might have a better idea.

We did...

Following very careful analysis of the noise sources and layout of the air conditioning plant and some lateral thinking, we designed an elegant solution involving a combination of:

- engineering control at source,

- innovative local acoustic treatments

- imaginative use of site geometry

- modifications to the chiller control system

The result was a set of modifications that were easy to implement in convenient stages and reduced the data centre AHU noise by 15dB(A) at a cost of c £40,000 – and with no effect on the normal operation or the overall efficiency of the system - unlike the previously proposed conventional noise barriers and silencers.

How to attenuate the noise from data centers

More details of the best approach to reducing the noise from chillers and air conditioning plant >

Chiller noise control costs were cut by 80% using new technology. The company running a server farm had spent £100,000 on noise control measures (acoustic barriers and silencers) for their HVAC and AHU plant to no avail – the complaints continued as the noise levels were virtually unchanged. We were invited by the Local Authority to provide both parties with a definitive statement as to what constituted “best practicable means” and to sort the problem.

Careful diagnosis allowed us to generate a best practice noise control package that would eliminate the problem at a cost of c £30k.

These measures included purpose designed silencing, geometry changes, improved acoustic screening and internal modifications to the main Air Handling Units. On the air conditioning condenser units, we by-passed the conventional solution of noise barriers and silencers as these are not only high cost control measures, but they can also reduce the efficiency of the chillers themselves. Our alternative was a set of low cost engineering noise control modifications that not only reduced the overall noise from the HVAC plant at source by 8dB(A), but also eliminated the hum (worth an additional 5dB(A) noise reduction with respect to environmental noise limits) – and with no effect at all on the chiller condenser performance or access.

The result was an overall noise reduction of 12dB(A) and the elimination of the tonal content of the noise from the condensers. If best practice had been used at the start, the company would have reduced the cost of the chiller plant noise control project by 70% and avoided several months of management hassle and a sacking…

Cooling tower fan silencing by conventional means is often both very difficult and very costly as the problem is usually low frequency in nature so conventional silencers and noise barriers don’t work. Despite this fact, the cooling tower world is awash with placebo silencers and acoustic barriers that are just a waste of money. Alternatively…

… quite often there are low-cost source control alternatives. For example, the dominant environmental noise problem from a food processing plant in the middle of a village was caused by cooling tower noise from a pair of units – despite the large silencers already fitted to the axial fan exhausts. We devised engineering modifications that produced a substantial improvement in the efficiency of the cooling towers that, coupled with measures to reduce the noise from falling water, not only cut the overall noise level from the units by 15dB(A), but also substantially reduced running costs.

The noise from a pair of new cooling towers had ignited complaints from residents across the road from the site. A typical acoustic consultant was drafted-in who recommended the industry default silencers and a noise barrier without carrying out any diagnosis. Not good practice, let alone best practice.

The predicted effect on the plant noise of fitting the typical conventional acoustic package of silencers and a barrier along the edge of the site was to reduce the noise level down to around 56dB(A) at the neighbours - still far too high for the area. Despite a total cooling tower noise attenuation package costing well over £40k, not only would the problem not have been solved but in addition, as the acoustic barrier would have caused serious transport access problems, the company had to look for alternatives.

Our solution was based on a very accurate diagnosis and ranking of the cooling tower fan, drive and pump noise sources to develop an engineering source control package. The final noise reduction measures for both cooling towers comprised:-

- intake and drive motor modifications

- exhaust and pump silencers

- local acoustic screening

This package achieved a noise level of <50dB(A) at a cost of only £6k and without affecting normal site operation or cooling tower efficiency. Around 15% of the cost and more than 4 times the attenuation of the conventional noise reduction measures.

How to select the optimum cooling tower noise control measures >

A BP refinery in the USA had been quoted $1.25 million for five 1.5MW double entry ID combustion fan silencers to address the cause of extensive noise complaints. Their acoustic consultant had come across our aerodynamic fan noise control technology on the web and contacted us for advice. He sent his noise data to us by email and we identified that our technology would be ideal as an alternative to fitting fan silencers.

We used the information provided to design the aerodynamic modifications to generate drawings that would allow the components to be made by local contractors. After an installation process that required a tiny fraction of the downtime associated with fitting attenuators, the 180Hz blade pass tone had been completely eliminated (>12dB reduction), preventing any further noise complaints.

The quotation for fitting conventional silencers or mufflers totaled $1.25 million with additional costs associated with the extensive downtime required to fit the attenuators plus increased running costs.

The total project cost for all the aerodynamic modifications not only saved over $1,000,000 from the $1.25 million quotation for conventional silencers, but, in contrast with traditional mufflers, the modifications had no effect on fan efficiency (reduced running costs) and will last the lifetime of the fan with zero maintenance.

No site visits were required, saving time, resources and carbon (transatlantic flights etc). A very self-financing project...

More details of how to reduce ID fan noise using our aerodynamic noise control technology.

More information about our remote control of noise technology used for this ID fan project.

The noise from a 3m, 1.5MW wood-burning biomass boiler combustion ID fan installed at the Schiller power station in New Hampshire (one of the largest renewable energy projects in the U.S.) was dramatically reduced using innovative technology to replace the traditional silencer fitted to the power station fan. Our aerodynamic noise control technology not only cut the noise at source, but also substantially increased the fan efficiency.

The ID fan feeds a stack through a system that included a very large conventional silencer to prevent noise complaints from local residents. As this muffler had a drastic impact on fan efficiency, it had to be removed. This had a serious impact on the local environment, generating a host of complaints for which a very urgent solution was required.

Our aerodynamic source control technology was retrofitted instead of the attenuator within an incredibly short 12-hour downtime window. This not only eliminated the low-frequency tonal noise problem from this large industrial boiler system at a minute fraction of the cost of the silencer it had usurped, but as it also reduced the fan power consumption, the project was self-financing.

"The ID combustion fan created a low frequency tonal noise that could be heard on the other side of the river and was the cause of complaints. The installation process took only 12 hours, after which we recorded a huge 10dB drop in noise and measured a reduction in the power used by the ID fan.." Jim Granger, Senior Engineer, Schiller

This international project was managed remotely from our UK offices. By analysing and interpreting data acquired locally to our specifications, we were able to dispense with site visits and reduce the entire process, from initial contact to problem solved, to a matter of a few weeks.

Filtration (bag filters etc) and conventional attenuators reduce fan efficiency by adding back pressure. We use Computational Fluid Dynamics (CFD) modeling and past experience to determine exactly where changes can be made to reduce back pressure and hence improve system efficiency. For example, it is often possible to modify existing silencers to reduce back pressure - or even to eliminate these attenuators altogether by using alternative techniques to cut broadband noise without the hit on fan efficiency associated with conventional noise control measures..

The approach not only reduces noise, but it also cuts running costs and increases productivity. This renders noise control projects of this type highly profitable so that implementing the modifications would be a valuable exercise, even if there was no noise issue...

4 large axial extract fans caused noise complaints over a wide area in Canada, despite multiple attempts at noise control based on conventional techniques. One email led to the noise being reduced by 99% with no site visits required - the whole project was completed over the internet.

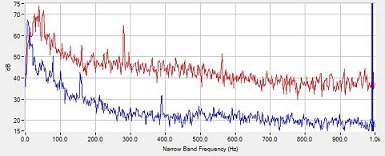

Mitchell, the site engineer sent us an email with smartphone video clips and photos. Soundtrack analysis showed the problem to be high-level tones at the 197Hz blade pass and harmonics. We used the photos to design retro-fit aerodynamic noise-reducing components which the client made and installed to give 20dB attenuation at 100m.

"We are exceptionally happy with the overall results that were obtained, from a noise reduction, cost, and time standpoint. INVC was very professional and prompt on all deliverables. Out of all solutions attempted this was by far the best and cost-effective. The whole process was very smooth from first contact to installation … glad we went with INVC, thanks…"

In addition to the attenuation of the primary fan hum sound, the harmonics and associated tones were also dramatically reduced as shown in this frequency analysis plot. Moreover, as the performance of the fans was also improved, the project was self-financing and will pay for itself in reduced running costs.

This technology is very applicable to all types of extract fans where tonal noise is an issue. As it is immune to the effects of the passage of materials or to corrosive atmospheres (it cannot clog), it is particularly suitable to attenuate the noise from fume, scrubber, dust, or other waste extract fans.

Proposed £100k conventional attenuators for 10 axial mine water evaporation fans in Australia would have had zero effect in the noise as it was predominantly low frequency tones (hum or drone). A few emails and <£20k gave 23dB noise reduction and improved efficiency.

The Australian mining company had a series of 10 large axial fans that are used to evaporate water pumped from underground. However, these fans had caused complaints over a very wide area. The quote for £100k of mufflers would have provided zero attenuation as they would be fitted only to outlets (half the noise is from the intakes) and they would provide virtually no attenuation at the dominant 200Hz tone.

Our remote noise control service diagnosis allowed us to evaluate the problem using information and recordings provided by email, saving a visit from the UK to Australia... We designed and emailed aerodynamic fan noise control modifications for local manufacture. These reduced the tonal content by 23dB at a cost of <£2k/fan. As fan efficiency was also improved, this was a profitable, self-financing project for the client.

As a result of complaints about noise from 2 large centrifugal fans on a factory roof and the involvement of the Environment Agency, the company spent £50k on traditional acoustic lagging that unfortunately had zero effect on the noise levels. This ineffective expenditure resulted in a prolonged wrangle with the authorities – who eventually suggested that they could get a 2nd opinion from us (based on our free analysis and diagnostic service).

They forwarded a video-clip and analysis of the sound-track proved that the problem was a pair of tones at the blade-pass frequencies of the 2 fans plus 1st harmonics that were interfering and “beating” with each other. We designed the solution in the form of aerodynamic Quiet Fan technology that provides retro-fit attenuation without using silencers. This eliminated the tones as a noise feature and the complaints ceased.

The whole process was completed within a few weeks at a tiny fraction of the cost of conventional alternatives. Moreover, only a single site visit was required – the rest of the work was carried out by email.

Your problem may already be solved

Search our worldwide best practice options

Free Remote Diagnosis

Email us a video from your smartphone for an evaluation of best practice