An elegant engineering solution to your noise or vibration problem may already be available. Search the largest database of noise control at source case studies in the world for best practice alternatives to conventional, high-cost palliatives such as acoustic enclosures, silencers, barriers etc.

As a result of complaints about noise from 2 large centrifugal fans on a factory roof and the involvement of the Environment Agency, the company spent £50k on traditional acoustic lagging that unfortunately had zero effect on the noise levels. This ineffective expenditure resulted in a prolonged wrangle with the authorities – who eventually suggested that they could get a 2nd opinion from us (based on our free analysis and diagnostic service).

They forwarded a video-clip and analysis of the sound-track proved that the problem was a pair of tones at the blade-pass frequencies of the 2 fans plus 1st harmonics that were interfering and “beating” with each other. We designed the solution in the form of aerodynamic Quiet Fan technology that provides retro-fit attenuation without using silencers. This eliminated the tones as a noise feature and the complaints ceased.

The whole process was completed within a few weeks at a tiny fraction of the cost of conventional alternatives. Moreover, only a single site visit was required – the rest of the work was carried out by email.

Highly tonal noise from these chillers had been the cause of complaint for some considerable time. The company had already attempted acoustic enclosure with the result that the chillers had over-heated.

The EHO sent us sound recordings, photographs and noise levels. Once analysed, we were able to say that the noise problem could be resolved for a few hundred pounds without running the risk of chiller problems. Once this information was passed on to the garage, they contacted us and we supplied them with detailed drawings that they used to get the silencers made locally.

Problem solved…

A BP refinery in the USA had been quoted $1.25 million for five 1.5MW double entry ID combustion fan silencers to address the cause of extensive noise complaints. Their acoustic consultant had come across our aerodynamic fan noise control technology on the web and contacted us for advice. He sent his noise data to us by email and we identified that our technology would be ideal as an alternative to fitting fan silencers.

We used the information provided to design the aerodynamic modifications to generate drawings that would allow the components to be made by local contractors. After an installation process that required a tiny fraction of the downtime associated with fitting attenuators, the 180Hz blade pass tone had been completely eliminated (>12dB reduction), preventing any further noise complaints.

The quotation for fitting conventional silencers or mufflers totaled $1.25 million with additional costs associated with the extensive downtime required to fit the attenuators plus increased running costs.

The total project cost for all the aerodynamic modifications not only saved over $1,000,000 from the $1.25 million quotation for conventional silencers, but, in contrast with traditional mufflers, the modifications had no effect on fan efficiency (reduced running costs) and will last the lifetime of the fan with zero maintenance.

No site visits were required, saving time, resources and carbon (transatlantic flights etc). A very self-financing project...

More details of how to reduce ID fan noise using our aerodynamic noise control technology.

More information about our remote control of noise technology used for this ID fan project.

4 large axial extract fans caused noise complaints over a wide area in Canada, despite multiple attempts at noise control based on conventional techniques. One email led to the noise being reduced by 99% with no site visits required - the whole project was completed over the internet.

Mitchell, the site engineer sent us an email with smartphone video clips and photos. Soundtrack analysis showed the problem to be high-level tones at the 197Hz blade pass and harmonics. We used the photos to design retro-fit aerodynamic noise-reducing components which the client made and installed to give 20dB attenuation at 100m.

"We are exceptionally happy with the overall results that were obtained, from a noise reduction, cost, and time standpoint. INVC was very professional and prompt on all deliverables. Out of all solutions attempted this was by far the best and cost-effective. The whole process was very smooth from first contact to installation … glad we went with INVC, thanks…"

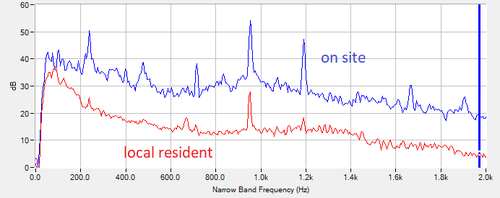

In addition to the attenuation of the primary fan hum sound, the harmonics and associated tones were also dramatically reduced as shown in this frequency analysis plot. Moreover, as the performance of the fans was also improved, the project was self-financing and will pay for itself in reduced running costs.

This technology is very applicable to all types of extract fans where tonal noise is an issue. As it is immune to the effects of the passage of materials or to corrosive atmospheres (it cannot clog), it is particularly suitable to attenuate the noise from fume, scrubber, dust, or other waste extract fans.

Attempts are often made to solve classic low-frequency chiller AHU fan noise using conventional silencers and noise barriers. Despite the fact that there is zero chance that these techniques can work at low frequencies, a fortune is still wasted every year on these useless palliatives. As air handling units (AHUs) on industrial sites, offices, supermarkets and other retail premises are such a common noise problem that you would expect better solutions based on a better understanding of the issues.

AHU noise control failings...

Previous failed attempts on this air-cooled chiller (48.5Hz and harmonics) were replaced with aerodynamic techniques that reduced the tones by 95% and improved the fan efficiency – all by email via forwarded video clips and photos.

The company had already tried using a barrier to mitigate the noise complaints to no avail. This is because barriers are almost completely ineffective at frequencies below around 200Hz (heard as drones, hums etc). Chiller and AHU fans regularly generate low-frequency tones as the blade pass hum often falls in this range. Whilst acoustic barriers and attenuators can be used to reduce the overall dB(A) noise level, they do not touch the low-frequency tones that are very commonly the actual cause of complaints. Our analysis of emailed video clips can immediately confirm whether this is the case, avoiding potentially costly mistakes. In contrast, our aerodynamic axial fan noise reduction technology addresses the low-frequency noise problem by reducing it at source with increased fan efficiency as a common additional benefit.

What are the air handling unit noise sources?

Typically, there are only 3 sources/types of noise generated by AHUs. They are:-

- Broadband air noise ("rushing sound") from the fans across a wide range of frequencies. This dominates the headline dB(A) noise level and can be attenuated by conventional silencers, barriers and enclosures. However, these can significantly reduce the system efficiency, adding to the cost.

- Low-frequency tonal noise ("hum or drone") at the blade pass frequency of the fans. These do not usually contribute anything at all to the overall dB(A) figure - and yet are a very common cause of complaints. They cannot be attenuated significantly using conventional means, the only effective solution is to use low-cost aerodynamic technology, technology that will often increase fan efficiency, reducing the cost still further (self-financing).

- Mechanical noise due to vibration transmitted into the support structure and then radiated as sound. Tonal at the motor speed and higher harmonics. The best solution is usually very low-cost retrofit high-performance damping.

When considering the options to reduce air handling unit noise, it is vital to diagnose the precise nature of the noise problem and which source(s) are responsible to avoid wasting money on the wrong solution. For example, the solution recommended by consultants to cut complaints re noise from roof-mounted AHUs in London was to replace one of the units with a quieter model. This cut the noise on the roof by 7dB(A). However, the complaints continued as they were caused by low-frequency fan tones from a different unit.

The lack of a correct diagnosis cost that client over £100k...

Click this link for more detailed information on the best approach to noise attenuation for chiller, air condenser, HVAC and refrigeration fans.

Cooling tower noise had triggered complaints as the noise was highly tonal. This led to a £31k quote from the supplier to replace the whole fan drive unit and fit acoustic treatments on the recommendation of their noise consultant.

The local EHO suggested they contact us for a 2nd opinion.

We asked for a video clip by email, analysis of which allowed us to determine from the gearbox details forwarded that the problem tone was at the tooth meshing frequency of the pinion gear. As a result, the gearbox pinion gear was rapidly replaced at a cost of £3k.

The whole diagnostic process from the 1st phone call to analysis to the provision of a detailed proposed solution took just 20 minutes, all of which was spent in the office…

This cooling tower noise reduction project is yet another example of the very poor diagnostic and engineering knowledge of many noise consultants. Far too often, decisions about noise control measures are made based on assumptions about noise sources rather than on accurate and precise diagnosis. There is a simple diagnostic process that must be followed when evaluating cooling tower noise control projects. This case study illustrates the power of simple, accurate diagnosis to remove all guesswork in solving noise problems quickly and at very low cost.

Detailed guide to selecting cooling tower noise attenuation techniques >

Low frequency (c 149Hz) tonal noise from a large variable-speed ID fan venting via an 83m high stack had caused complaints over a wide area. The company had spent considerable time trying (and failing) to find a practical conventional mitigation solution. We designed a bespoke stack silencing system that completely eliminated the problem noise without affecting fan efficiency. However, complaints then recurred post silencing that, as it turned out, were being wrongly attributed to our clients' site. This was potentially awkward as the Environment Agency was involved.

Telepresence - using a virtual expert on site

As the Environment Agency (EA) was involved, the site manager wanted to resolve the situation as rapidly as possible. He linked with us via Whatsapp on his phone, using the app to forward a couple of video clips. These allowed us to identify instantly that the complaints were now being caused by a tone at 346Hz and that the source was a small fan on a neighbouring site. After contact, they emailed the fan details and we designed an aerodynamic insert silencer that was manufactured locally and fitted within hours to eliminate the tone. This very rapid process (a few days) avoided the potential further involvement of the EA and ensured that removing the nuisance to the local residents was fast and effective.

This plot shows the overlayed noise signatures of both the stack and small fan noise before and after silencing based on smartphone data. You can listen to the audio at the top of the page showing the effects of the modification - view the video on which the analysis was based here >

A consultant and materials supplier had encountered a complex industrial environmental fan noise problem as multiple rooftop fans were potential noise sources. Whilst on-site, he recorded audio both at the complainant and close to each fan. Unfortunately, it was a very windy day and hence the audio was overloaded most of the time. However, we are able to extract very short samples between wind gusts - as in the sound sample above that also includes the "after the fan noise attenuation" recording during more clement weather...

This enabled us to identify the only fan that matched the frequency of the whine at the complainant - this was a fan that had been previously discounted as a potential problem as it was already fitted with the 2 conventional attenuators visible in the picture.

This analysis (taken from the sound samples above) illustrates that, despite the wind noise, we were able to extract enough information to diagnose which fan was the cause and to devise a solution that permanently eliminated the complaints. This whole process was accomplished within a couple of weeks without a site visit.

Misdiagnosis of problem CHP noise sources is a common and costly mistake that is easily avoided.

The cause of low-frequency hum noise complaints from residents had been misdiagnosed in multiple reports. Consequently, no solution had been found despite extensive resources invested by both the company to whom the problem tonal noise had been ascribed and by the Environment Agency (EA). When contacted, we provided both our client company and the EA with the list of smartphone video recordings needed for the diagnosis, namely a recording close to each potential source plus off-site samples. This allowed us to frequency match the tones at the resident with those from the various items of plant.

Diagnosis showed the noise complaints were due to a pair of tones at 71Hz and at exactly 75Hz. All previous evaluations had mistakenly used 1/3 octave frequency analysis and assumed there was a single tone (despite the "beating" between the 2 tones - see audio and below). We diagnosed that the 75Hz noise was from a CHP diesel generator set on the company site (75Hz is a classic generator tone), but the other 71Hz tone was from a chiller on another site. We recommended a tuned exhaust silencer that eliminated the generator set tone. The 71Hz tone can easily be resolved using aerodynamic fan noise control technology.

Poor CHP noise diagnosis and reporting

This plot shows an overlay of a 1/3 octave analysis of the noise at the complainant and the (correct) narrowband analysis. This illustrates an all too common mistake by noise consultants using inadequate frequency analysis to investigate tonal noise problems. In this case, both problem tones are more or less in the same band (the 71Hz also contributes to the 63Hz band), hence the mistaken diagnosis that wasted considerable time and resources for both the company and the EA. As capable (free) FFT analysis phone apps are available, you have to question the competency of consultants using 1/3 octave frequency analyses to investigate tonal noise sources.

The correct noise diagnosis process for diesel generators

Base precise, low-cost noise control measures on narrowband frequency analysis of the tones causing complaints that provides objective evidence of the subjective problem in a form that closely matches the human response. This makes it the ideal metric to assess tonal noise nuisance.

In addition, it also provides very accurate and precise diagnostic information about the noise source. In this case, for example, we know both from calculation and experience that exactly 75Hz is a common tone in diesel generator set noise when connected to 50Hz mains supplies and that 71Hz is in the common range for chiller fan tones.

Diesel generator hum - the simple solution...

A simple off-the-shelf tuned exhaust silencer fitted to the CHP diesel engine reduced the problem 75Hz tone by c 19dB, eliminating this element of the nuisance noise.

View a detailed review of diesel generator set noise control best practice here >>

The noise from a set of anaerobic digesters (AD) had caused complaints from nearby residents that resulted in a Noise Abatement Notice. The company employed noise consultants and installed partial enclosures and barriers round the mixer motors and gearboxes on the AD tanks. The subsequent noise report concluded that there was no longer a significant noise impact from the operation of the plant as the attenuation measures had significantly reduced the noise breakout from the mixer motors.

This conclusion was simply wrong and the complaints continued.

The BS4142 report generated by the consultant was based entirely on overall dB(A) and third-octave band noise level measurements. Despite the fact that the complaints were about tonal noise, no detailed frequency analyses were carried out. This is a common failing in environmental noise reports, as is the lack of knowledge about effective best practice engineering noise control options.

We requested smartphone video clips when the company contacted us. From these, we were immediately able to diagnose that the only problem was a 953Hz tone at the gearbox gear mesh frequency as shown in this plot. We were also able to provide detailed engineering noise control recommendations, including the high-efficiency damping of specific components to reduce the gear mesh vibration re-radiated as noise. The complaints have ceased...

You can view the video on which the process was based here >

Client smartphone recordings before and after fan modification

A high amplitude hum was the cause of noise complaints, both off-site and in the site offices. Short smartphone audio recordings taken in the office and at 10m and 50m from the fan were emailed to us for analysis along with photos of the fan installation.

This analysis showed the hum to be tones at 180Hz and harmonics, matching the blade pass frequency (1800rpm, 6 blades). A silencer had already been fitted to the fan, but this was ineffective due to the low frequency.

We designed an aerodynamic insert to cut the hum at source, simultaneously reducing noise from the intake, the outlet and through the previously fitted enclosure. This was manufactured and installed by local contractor within a few hours downtime (resources required: a fitter for 1 day, materials $70).

This reduced the hum by 25dB, solving the problem with no effect on the fan performance.

The noise from the Eurostar Nightstock HVAC module (140 had been built) was unacceptable in terms of overall noise and tonal content at the fan blade pass frequency. Conventional noise control techniques (silencers) from the manufacturer had been unsuccessful.

Maintaining the fan performance was critical and space within the air conditioning system was severely limited and a retro-fit solution was needed very quickly. The optimum solution involved a combination of Quiet Fan technology with a new 7 bladed impeller design that could be fitted very quickly at low cost and entirely within the existing HVAC unit i.e. no space implications. This reduced the annoying blade pass tone by 24dB and the overall system noise by 8dB(A).

As the fan noise reduction modifications reduced the noise at source, they simultaneously treated the intake, exhaust and break-out noise through the fan casing. Conventionally you would have needed separate attenuators for each transmission path that would have had a catastrophic effect on HVAC system performance.

The whole project was completed within a few days.

As part of a continuous product development programme to maintain their world-leading reputation, CompAir asked us whether it would be feasible to re-design the noise control package on one of their compressors. The initial target was to remove the existing silencer element to reduce the overall size of the unit – without any increase in noise or a reduction in the performance of the cooling system.

Source control modifications were developed for the cooling system which significantly reduced the overall noise from this element at source and also dramatically cut the tonal content (less “nuisance”). Coupled with modest flow and geometry changes, the new package reduced the overall “headline” noise from the compressor by 2 – 3dB(A), despite removing the standard silencer – and all without any cost or performance implications.

During the re-design exercise for a new model, the noise from this vacuum cleaner was not only reduced by a factor of 10 (10dB(A)), but the subjective character of the noise was also substantially changed by eliminating tonal components to make it sound “nicer” (a specialist technical term in acoustics!). The development process involved very detailed diagnostic analyses to rank the contributions from all the noise sources so that the optimum modifications could be designed. Consequently, the cost in the final new product of the designed-in noise reduction features was negligible.

The noise reduction programme result also had the side effect of making the vacuum cleaner sound more powerful…

Extensive and very detailed diagnosis and analysis techniques led to the devlopment of an engineering noise control at source kit for this Molins making machine. It reduced the noise by 4dB(A) at very low cost and without affecting normal access or operation (unlike previous suggestions involving acoustic screens) which was sufficient to avoid mandatory hearing protection.

It was licensed by the manufacturer so that they could provide a very profitable retro-fit or overhaul option service worldwide. This illustrates the commercial opportunities inherent in the engineering noise & vibration control technology in which we specialise.