Worldwide Environmental Noise Reduction - faster and 80% lower cost technology

Think “Best Practicable Means” (BPM or BAT) in environmental noise control and you will almost certainly end up with our award-winning technology instead of conventional high-cost palliatives such as acoustic enclosures, barriers and silencers. Use our free Remote Control of Environmental Noise service for an instant evaluation of best practice by email.

This approach reduces noise control project costs by 50% – 80% and project times from years to weeks. Previous clients have saved $1 million on a $1.25 million contract and £28k on a £31k quote by emailing us smartphone data for a free 2nd opinion. Why not check your options?

Our unique environmental noise control technologies are widely recognised as defining current best practice. We are often retained by public bodies and industry to provide definitive rulings on what constitutes Best Practicable Means (BPM) or Best Available Technology (BAT). Environment Agencies and Local Authority noise regulators regularly use our free smartphone "remote noise evaluation" service to save time and resources in conjunction with learning the skills on our bespoke BPM noise training workshops. This approach also makes our Noise Management Plans (NMP) the industry benchmarks.

How have we revolutionised environmental noise control?

1 Environmental Noise Control Best Practice Audit - by email or on-site

The BPM / BAT Audit provides you with a definitive cost/benefit analysis of the environmental noise control options for any noise problem using current technology. Extensive experience has shown that, in most cases, the noise reduction techniques suggested by noise consultants are not best practice. BPM definitions that typically reduce noise control costs by 50% – 80% compared with alternative evaluations are game-changers...

The remote email audit process involves the following steps:-

- Contact us early for an opinion – email information (smartphone clips, photos etc)

- Review data/reports + analyse soundtracks for expert opinion on options and BPM costs

This is a free, worldwide service to this point. See Remote Control of Environmental Noise for more details.

- Diagnosis and BPM evaluation – acquire more detailed information as required (email or site visit); provide a detailed evaluation of the noise control options using current BAT with costs and noise reductions. This is definitive evidence of best practice

- Court cases – this process usually avoids the courts as the costs of noise control are so much lower than expected

For many projects, the process can be carried out at little or no cost using smartphone data by email without a site visit. This is a swift way to get an instant opinion to determine what would constitute best practice (a large % of noise control projects are not based on current best practice) from anywhere on the planet.

Remote Diagnosis

Email us a video from your smartphone for free evaluation of best practice

Your problem may already be solved

Search our worldwide best practice options

Keep current with best practice innovation

Subscribe for the latest in techniques and best practice

2 "Greener Quieter" sustainable, or even carbon negative, noise control

Advanced diagnostic analysis techniques coupled with modern engineering noise control technologies allow us to design source control measures that dramatically reduce embodied carbon compared with traditional palliatives.

They can even render noise control projects profitable >>

Award-Winning Fan Noise Attenuation Technology

Rapid deployment, improved fan efficiency, lower costs and no maintenance

This unique INVC developed fan noise control technology is BAT for many fans – the most common environmental noise control problem. The key benefits are:-

- low cost: typically 10% – 30% of the cost of attenuators

- hygiene: no hygiene implications

- maintenance: none required for the life of the fan - cannot clog

- rapid deployment: can usually be installed in hours

- efficiency: large efficiency improvements compared with silencers

Our low-cost technology is applicable to the common noise hum problems caused by chiller, dry cooler, condenser, data center and HVAC fans where efficiency gains of up to 23% have been achieved. It is also equally applicable to reduce noise from sources such as cyclone separators.

The technology also cuts embodied carbon and can even make noise control projects carbon negative through reduced power consumption compared with a unmodified fans.

"Greeneer Quieter" sustainable noise control details >>

Low-Frequency Environmental Noise Nuisance – Diagnosis and Control

Low frequency (LF) noise is a challenging environmental noise problem and the cause of much angst and wasted time. We have developed a simple three-stage procedure and a set of diagnostic tools that are very effective at identifying:-

- whether there is an objective noise problem

- if there is, what is the source?

- what is the best solution?

This procedure reduces the time required to identify and resolve low-frequency noise problems from months or years to a few days. We have also developed novel solutions, including “Psychological Psylencing” (or acoustic camouflage) - see below.

Psylencer – Psychological Silencing – Acoustic Camouflage

This is an innovative, low-cost solution to some difficult environmental noise problems where sound with “character” causes complaints. It can be used in conjunction with noise control measures or where noise control would be too expensive or impractical. Based on research into the subjective response of people to noise, the system generates bespoke sculpted sound that “camouflages” nuisance features in the noise. It is a strange experience, encountering sound that you don’t consciously hear making those that you found annoying simply disappear… See the Edgware Road station case study for more or download the technical note here >

Construction / Demolition / Infrastructure Noise & Vibration

We not only provide a complete range of conventional services covering all aspects of environmental and occupational noise and vibration for construction, demolition and infrastructure maintenance industries, but also a range of additional innovative management and control techniques based on unique engineering expertise. These have not only re-defined best practice under the regulations and standards, but they have also dramatically reduced project costs and delays. Our reputation is based on the results we have achieved by introducing these new procedures and techniques into a largely traditional industry.

Very good at problem-solving on complex projects and have more than saved their fees by astute forward-thinking and design solutions that made our very large and complex project better for them being onboard. In essence, we are delighted with INVC performance. Chris Burns, Senior Project Manager, Capital and Counties

EHO friendly SiteNoise web portal - reduce data management and reporting time

Automated noise, vibration and dust reporting + management tools; stores and plots all data from any source, providing controlled access to current and historical values from anywhere. Where appropriate, we also use Computer aided noise modeling to provide detailed information that can be used to evaluate the optimum noise control package for a site.

Mitigation and Noise Control – fewer complaints, extended working hours…

We have developed new technologies and techniques that can reduce noise levels by 5 – 10dB more than typical conventional measures – sometimes sufficient to allow extended working hours.

Psychological Silencing – acoustic camouflage, hiding nuisance noise, reducing complaints

Sculpted sound signatures that can sometimes hide site noise cheaply and quickly. Acoustic Camouflage makes use of specially designed artificial background sound to hide nuisance noise. This has been used very successfully on rail and construction projects to reduce or eliminate complaints about certain noise nuisance noise elements. Get the technical note on our Acoustic Camouflage here >

Technical Training Workshops – improving best practice expertise on site

1 - 2 day pragmatic guides for site personnel in noise and vibration measurement and management best practices. How to create and implement plans to meet Best Practicable means (BPM) management requirements to minimise noise and vibration complaints, including Section 61 applications. Options include short briefings up to full competency, in person or online.

PR and Multi-Media Presentations – changing perceptions, reducing complaints

Interactive demonstrations to inform and reassure stakeholders reduces the perception of nuisance. Extensive experience has shown that presentations using multi-media and interactive demonstrations to demystify noise and vibration are a very effective part of the process to reduce the likelihood of complaints.

VAT Analysis (Vibration Analysis of Transmission) - controlling transmitted vibration

The technique provides rapid, low cost evaluation of the transfer paths from plant vibration and the resultant vibration in a party wall or another structure. It detects bridging between party walls, enables zoning of areas by allowable vibration (light and heavy breaker zones etc) and facilitates optimum placement of vibration break cuts to maximise productivity.

Approaching £50000 had been spent on silencing two large, roof mounted fans in an attempt to satisfy local complainants and the Environment Agency authorities – unfortunately without any success due to a lack of diagnosis of the cause of the noise problem. When the company approached us to provide them with a solution, we asked them to email us a couple of video clips of the fans.

Our initial diagnostic analysis of the video sound-tracks showed that the noise issue was caused by the interaction between the blade pass tones of the 2 similar fans that caused "beating" - modulation of the tonal level that adds to the subjective nuisance. This allowed us to design our unique Quiet Fan technology aerodynamic inserts to reduce the noise by over 20dB at source without enclosures, silencers or lagging – permanently and without maintenance. This was achieved with minimal down-time and at a tiny fraction of the cost of conventional alternatives. Read more on fan noise control without attenuators.

Conventional extract fan silencing is not only subject to clogging, but can also increase backpressure, reducing system efficiency - not what you need from an extract system that is intended to protect operators from fume hazards.

However, there are elegant, innovative and low-cost solutions that:-

- reduce fume or dust extract LEV fan noise to reduce both environmental complaints

- reduce occupational noise hazards

- can substantially improve LEV performance and operator safety

Solving the low frequency noise problem

A large weld booth fume extractor fan system generated high-level low-frequency tones at 35Hz and harmonics that caused extensive complaints in nearby offices. Diagnostic measurements proved that the major problem was an in-duct standing wave resonance in the manifold that was amplified by panel resonances in the filter enclosure.

The engineering solution involved:-

- designing an aerodynamic insert that was fitted in the ductwork to reduce turbulence

- fitting an acoustic absorbent plug into an end cap to create an anechoic termination to destroy the standing waves

- applying stiffening ribs to the filter enclosure to detune the noise radiating panels

These measures were fitted within a single day at very low cost to eliminate the low-frequency tones (a 30dB reduction).

Improving the LEV weld extract system performance

The first step in our approach to attenuate LEV fan noise is to develop modifications to improve the system efficiency as this also reduces noise (noise is wasted energy).

In this case, the aerodynamic modifications we designed to cut the noise also dramatically improved the fume extract fan system efficiency, improving safety and reducing running costs.

This approach based on our expertise in fan systems can be used to improve LEV extract efficiency, even where noise is not an issue...

View the detailed guide to fume and scrubber extractor fan noise reduction and silencing techniques.

Data centres (or "data centers" in the US) require a lot of cooling - which involves noisy chiller fans, air handling units (AHUs), cooling towers and condensers. Moreover, in addition to the general fan air noise, there are often low-frequency tonal elements (hums or drones) that cannot be silenced using conventional attenuators and acoustic enclosures and barriers. Unfortunately, poor diagnosis of the exact causes of noise complaints has often led to ineffective control of the noise from data centers that not only fail to solve the problem, but also compromise cooling efficiency.

Fortunately, there are effective low-cost alternatives that can actually increase cooling capacity...

Data centre noise problems - low-cost precision attenuation

A Noise Abatement Notice had been issued re the AHU noise from a large array of chillers at this data centre. The company had already spent nearly £100k on noise control with very little success and was considering claiming Best Practicable means (BPM) in court when the council suggested they might like to get a second opinion from us to avoid the legal route…

We carried out a very accurate diagnosis of the precise noise elements that were the cause of the complaints. Based on this evaluation, we designed a set of precise retrofit noise reduction measures that were guaranteed to be BPM. The innovative noise control measures included:

- Air handling units: changing the geometry of the AHUs and introducing internal modifications to convert existing elements into effective acoustic attenuators cut the broadband noise by >10dB(A) with no effect on fan efficiency

- Chiller condenser fans: the noise from these units was reduced by fitting a combination of high-efficiency damping coupled with internal and fan modifications, reducing the overall noise by around 8dB(A) with no effect on performance. Improvements were also made to the existing noise barriers.

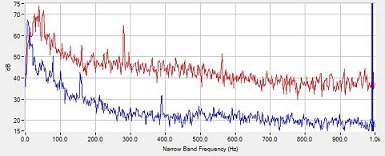

These noise mitigation measures cut the overall noise at the complainants from 48.5dB(A) down to 36.5dB(A) (as illustrated by the audio recording above and by this noise signature) without affecting the performance of the cooling systems. In addition to the reduced broadband noise, the tonal "character" of the noise was also eliminated.

The whole process took approximately 6 weeks from start to finish and completely resolved the complaint issue.

Cost savings on noise control

The overall effect was to reduce the data centre cooling system noise by 15dB at less than half the previously expected cost. If this approach had been implemented in the first place, the company would have saved over £100k, the council would have saved resources and the complainants would not have had to suffer unnecessary disturbance over a 2 year period.

More details on how to reduce environmental noise from data centers

More on chiller, condenser and heat exchanger AHU fan noise reduction.

Planning - noise site blight

High levels of environmental noise from nearby industrial premises were affecting over 18 acres of mixed brown-field and farmland. Combined with the fact that there had already been many noise complaints from nearby residents, the planners assessed the site as unsuitable for housing.

However, the City Council wanted to allow the development if the noise issue could be resolved. Aware of our expertise in industrial and fan noise control, they suggested that the Planning Consultants contact us for a second opinion to see if there was a practical solution.

Diagnosis

We acquired information from the council about the history of complaints and considered that it was very likely that it would be practical to reduce the noise across the site by applying permanent engineering noise control measures to the problem items of plant.

Noise control implementation

Based on our judgment, the developers invested in our expertise to evaluate the noise control options in detail and to design permanent solutions (including our Quiet Fan noise control technology for the problem fans) that could be implemented (paid for by the developer) at each of the 4 companies involved. The companies were extremely happy with the process as this resolved the previous and ongoing noise complaints at no cost to them.

The environmental noise environment for nearby residents was dramatically improved and the council saved on future noise complaint investigation resources.

The noise mitigation measures permanently eliminated the environmental noise problem, allowing the "noise planning blight" to be lifted. Consequently, planning consent was granted for 200 properties to be built on a site previously considered too noisy for housing. This not only made the site worth many £millions at a cost to the developers of less than £45k, but it also provided 200 much-needed houses.

From regular noise complaints to less than zero complaints…

As the station is overlooked by apartments, nighttime noise from underground track maintenance activities had given rise to regular complaints from local residents. The contractor, Balfour Beatty, decided to be proactive by asking us to introduce our new Acoustic Camouflage technology.

This solution involved relocating welfare facilities to take advantage of existing site screening features coupled with temporary acoustic barriers – not just for the facilities, but also for the vehicles and workforce at the station entrance. Then a pair of Acoustic Camouflage systems were installed at the station entrance and near the welfare area to dispense non-directional, shaped signature background noise. Despite raising the background noise by 8dB(A) at key locations, it was subjectively inaudible on the other side of the street. As a result, these systems were very successful at camouflaging the key annoying elements in the noise from the site activities.

The end result was not just to reduce the number of complaints to zero, but congratulatory emails were received from previous complainants complimenting the company on the effectiveness of their noise management...

Boiler burner noise complaints

The cause of complaints about environmental noise levels was traced to this dual fuel burner boiler on a Heinz site. The company contacted us to assess the noise control options as the conventional palliative noise control techniques for this sort of problem involve fitting large silencers into the stack and converting the boiler house into an acoustic enclosure – eye-wateringly expensive with extensive downtime (which would have caused serious production problems).

The (blackcurrent) solution

The source was diagnosed as a 116Hz low frequency “drone”, a very common type of burner noise control problem. We developed a stunning simple alternative solution that comprised a set of aerodynamic modifications that fitted inside the combustion head. The initial trials were conducted using an adapted yoghurt pot fitted inside the burner head – as far as we know, this is the only known yoghurt-based noise control application…

The modified pot reduced the drone by 16dB, completely eliminating the problem.

The cost? Less than £2k with a downtime of a few hours (aluminium version of the yoghurt pot). This new approach and technology can be an incredibly cost-effective solution to many burner or combustion noise problems - and can reduce fuel consumption...

Industrial boiler burner noise attenuation

There are usually only 2 noise sources on industrial boilers and burners:-

- combustion fan: broadband and/or tonal noise at the fan blade pass frequency. Easily controlled using a simple silencer and/or aerodynamic fan noise control technology

- combustion noise in the boiler burner: broadband sound - but very often with a pronounced low-frequency signature (and sometimes pure tones) that can travel large distances (a common cause of complaints). Traditionally, the suggestion is often to spend a large fortune to turn the boiler house into an effective acoustic enclosure. Our alternative is to address the problem at the source - as above...

The highly tonal noise from corrugators and slitters at Northern Packaging, the premiere packaging company in the north of England, had caused complaints from local residents and was subject to an abatement notice. The company was quoted £150,000 for conventional environmental noise control (building modifications) but with no guarantee it would solve the problem. An EHO who had been on one of our BAT courses suggested we might have an alternative approach.Following a best practice audit, we developed noise control at source engineering modifications to cut the noise generated by the corrugator and slitter machines inside the building. Installed by Sound Damped Steel, these not only reduced the problem tonal noise by up to 9dB, but also eliminated the requirement for mandatory PPE – a double benefit. In addition, the cost was only c£25,000, an 80% saving over the proposed conventional noise control methods.

This is a typical example of the success of our approach to environmental noise problems, re-defining noise control best practice by developing elegant engineering solutions in place of the high cost, conventional palliatives usually considered. Moreover, to the delight of the company, the project also satisfied their mandatory noise control requirements under the Control of Noise at Work Regulations – at no added cost. This approach should be standard practice for environmental noise pollution problems. Controlling noise at source is always the first step in the process of defining BAT or BPM.

A new CHP installation on a large industrial site next to a housing estate was subject to very stringent planning constraints with respect to noise. A full impact assessment was made and, in conjunction with both the supplier and the Local Authority, a detailed noise specification drawn-up for all components of the installation.

We not only produced the noise specifications, but also provided detailed engineering noise control measures for the CHP installation project. An innovative approach was used to cut the expected cost of the overall noise control measures to meet the noise specification by approaching 90% by developing low cost engineering modifications to reduce the noise from other contributory sources on the site (fans, compressors, pumps, gas mains...) at the nearest dwellings by 8dB(A). This meant that the stringent noise attenuation requirements for the CHP installation could be significantly relaxed to generate very substantial cost savings.

Local residents were complaining about low frequency noise and vibration from a large tunnel operation which also exceeded the overall planning consent noise levels. The low frequency noise and vibration was generated by the spoil processing vibratory sieves and the previously proposed remedial measures included a deep ditch and a very large barrier. Neither of these would have been effective...

Our detailed diagnosis showed that the main problem was caused by excitation of some of the steel building wall and roof panels that then radiated the vibration very efficiently as noise. The panels we had identified as a problem were de-tuned quickly and cheaply by introducing stiffening ribs. This reduced the 15Hz noise radiation by 8dB which was sufficient to prevent further complaints.

We have also generated a comprehensive technical note on all aspects of vibratory feeder, hopper, conveyor and grader noise...

Complaints about press noise from a factory unit had resulted in an Abatement Notice from the Local Authority. After the company had spent over £12000 on the building to no avail and with another £65000 expenditure planned as recommended by noise consultants (but without any guarantee that it would solve the problem), they had decided to challenge the notice in court.

However, as our Best Practicable Means (BPM) Noise Control Audit for the Local Authority proved that the best solution was to treat the small number of power presses that were causing the issue at source at a fraction of the cost of legal fees, this approach was adopted by the company. The engineering source control measures reduced the low frequency noise components by 9dB - 24dB, eliminating further complaints. This is a classic case where consultants have not carried out detailed diagnostic work to identify the precise causes of complaints, who do not have the engineering skills needed to design source control modifications and are therefore limited to recommending conventional palliatives that are not best practice at a very high cost to the client, the LA and to the disturbed residents.

£250 000 cost saving on environmental noise control…

Everyone knows that massive noise barriers are the only solution for noise from scrap yards and recycling centres. Everyone knows wrong...

We saved a scrap recycling company over £250 000 on the proposed noise barriers by controlling the dominant scrap impact noise at source. This is new technology that can reduce the impact noise from crushers in quarries, dump trucks, shredders, trains, manual handling etc by up to 15dB(A). Compared with conventional noise control techniques, the cost is miniscule, it is incredibly rugged, can be fitted very quickly and has no effect on plant operation, maintenance or access.

Noise levels from a power station were uncomfortably close to the environmental noise planning conditions, but it was unclear which were the dominant noise sources.

Noise diagnosis

Detailed diagnosis proved that the dominant contribution was high-frequency noise (>500Hz) radiated by the Gas Reception Facility. Vibration measurements were used to calculate the proportion of the noise from the various plant elements so that their contributions could be ranked. The results were used to determine the minimum parts of the plant that would require attenuation in order to meet the noise specification.

This process showed that is was only necessary to treat the reducer, expander and associated valve section of the facility instead of the much larger areas previous considered, saving a considerable sum.

Noise mitigation measures

We provided details of our innovative, high-performance acoustic lagging that was manufactured and installed by Sound Damped Steel. This has an outer skin constructed from highly damped laminated steel, making it very tolerant of installation practicalities. Moreover, we have also developed versions that eliminate the corrosion problems inherent in conventional lagging designs that almost invariable leak, causing hidden corrosion.

The diagnostic process illustrates how costs can be kept to an absolute minimum by precisely ranking noise contributions from different components, even amidst complex arrays of pipework, valves and other sources.

The effect of the treatment was to reduce the noise from this source by 16 -19dB(A), eliminating it as a contributor off-site. Occupational noise levels in the area were also reduced by an average of 8dB(A). More information is available on the Sound Damped Steel installer website here.

A detailed environmental noise impact assessment established 24 hour target noise levels for a new quarry as part of the planning submission. This was supported by predictions of the changes in the local noise environment throughout the working life of the quarrying project and a detailed compliance verification procedure.

Detailed Buy Quiet noise purchasing specifications were provided for every piece of plant to be installed within the quarry. These included the measurement procedures and the best practice noise control measures that should be used by the suppliers to ensure that the target noise levels were met as cost effectively as possible (most suppliers have very little knowledge of noise control engineering technologies).

Your problem may already be solved

Search our worldwide best practice options

Keep current with best practice innovation

Subscribe for the latest in techniques and best practice