An elegant engineering solution to your noise or vibration problem may already be available. Search the largest database of noise control at source case studies in the world for best practice alternatives to conventional, high-cost palliatives such as acoustic enclosures, silencers, barriers etc.

The noise from dozens of vibratory feed hoppers and separators in a pharmaceutical plant generating 95 – 99dB(A) was reduced by 22dB via retro-fit modifications to the geometry and the introduction of sophisticated damping. As an additional benefit, the modifications substantially improved product feed and eliminated persistent fatigue cracking. The cost was not only a tiny fraction of the c £100000 required to fit conventional acoustic enclosures, but there was no effect on access/cleaning (unlike acoustic enclosures) and productivity was significantly improved.

A similar approach has also been successfully applied to control the noise from vibratory bottle feeders to give an 8dB(A) reduction at a cost of c£500 and with substantially improved performance and productivity.

Contact us if you'd like to discuss a particular project.

We have also generated a comprehensive technical note on all aspects of vibrating feeder, hopper, conveyor and screen noise...

Other examples of our engineering vibratory system noise reduction technology include:-

Manufacturers are under increasing commercial pressure from their customers to develop low vibration plant. The innovative low-vibration handle developed by the INVC for a Dennis Mowers lawn-mower reduced operator exposure from 6m/s^2 down to 2m/s^2 – without compromising mower control. This is a dramatic improvement that would allow operators to use the mower all day without reaching the 2.5m/s^2 Exposure Action Value.

This was developed and tested in prototype form within around 4 hours of arriving on site...

Flash removal from hand-held aluminium components generated 32m/s^2 – the Exposure Limit Value (ELV) would be reached in 12 minutes, severely limiting production. Detailed analysis revealed dominant vibration was caused by a pedestal grinder component rest resonance. It was replaced by a floor mounted version that improved the ergonomics and reduced the vibration to 1m/s^2, allowing unlimited use without risk of HAVs.

A hand-held Ingersoll Rand sand rammer packing concrete lintel moulds generated 28m/s^2 with a maximum trigger time of only 15 minutes/day before reaching the ramming tool vibration control Exposure Limit Value, seriously limiting production. We designed a mass / sprung balance system that reduced the vibration to 11.5m/s^2, extending the “safe” trigger time to 90 minutes/day. Combined with substantial ergonomic improvements, operator HAVS risk was virtually eliminated and there were large productivity gains. As the whole project was completed within days (no site visit) via information (data, video) forwarded by email, the total cost was a few £hundred, making it self-financing over a few days.

Vibration from riveting on a bench jig posed a very high risk of HAVS. Our redesigned, stiffer jig reduced the riveting time by 50% and the vibration by 25%. This cut the overall operator dose by nearly 90% – improving productivity as a side effect.

The operator used a spanner on one side of conveyor frames and an impact wrench on the other, producing significant HAVS risk in both hands. We recommended a larger, more ergonomic spanner and a more powerful wrench. These measures halved the vibration dose and significantly improved productivity.

High-speed bits were used to trim aluminium panels, but the tool speed was far too low. Changing the die grinder for a high speed unit to match the bit left the vibration unchanged, but the improved efficiency cut working time from 20 minutes to 2 minutes, reducing the risk by a factor of three. On a similar operation, simply ensuring the grinding bit was pushed fully into the chuck reduced the level of vibration by a factor of x4.

Designing a shorter stirrer bar and reducing the speed of a hand held paint stirrer reduced the 30m/s^2 vibration level to 8m/s^2 without affecting performance.

The highly tonal noise from corrugators and slitters at Northern Packaging, the premiere packaging company in the north of England, had caused complaints from local residents and was subject to an abatement notice. The company was quoted £150,000 for conventional environmental noise control (building modifications) but with no guarantee it would solve the problem. An EHO who had been on one of our BAT courses suggested we might have an alternative approach.Following a best practice audit, we developed noise control at source engineering modifications to cut the noise generated by the corrugator and slitter machines inside the building. Installed by Sound Damped Steel, these not only reduced the problem tonal noise by up to 9dB, but also eliminated the requirement for mandatory PPE – a double benefit. In addition, the cost was only c£25,000, an 80% saving over the proposed conventional noise control methods.

This is a typical example of the success of our approach to environmental noise problems, re-defining noise control best practice by developing elegant engineering solutions in place of the high cost, conventional palliatives usually considered. Moreover, to the delight of the company, the project also satisfied their mandatory noise control requirements under the Control of Noise at Work Regulations – at no added cost. This approach should be standard practice for environmental noise pollution problems. Controlling noise at source is always the first step in the process of defining BAT or BPM.

Approaching £50000 had been spent on silencing two large, roof mounted fans in an attempt to satisfy local complainants and the Environment Agency authorities – unfortunately without any success due to a lack of diagnosis of the cause of the noise problem. When the company approached us to provide them with a solution, we asked them to email us a couple of video clips of the fans.

Our initial diagnostic analysis of the video sound-tracks showed that the noise issue was caused by the interaction between the blade pass tones of the 2 similar fans that caused "beating" - modulation of the tonal level that adds to the subjective nuisance. This allowed us to design our unique Quiet Fan technology aerodynamic inserts to reduce the noise by over 20dB at source without enclosures, silencers or lagging – permanently and without maintenance. This was achieved with minimal down-time and at a tiny fraction of the cost of conventional alternatives. Read more on fan noise control without attenuators.

Conventional extract fan silencing is not only subject to clogging, but can also increase backpressure, reducing system efficiency - not what you need from an extract system that is intended to protect operators from fume hazards.

However, there are elegant, innovative and low-cost solutions that:-

- reduce fume or dust extract LEV fan noise to reduce both environmental complaints

- reduce occupational noise hazards

- can substantially improve LEV performance and operator safety

Solving the low frequency noise problem

A large weld booth fume extractor fan system generated high-level low-frequency tones at 35Hz and harmonics that caused extensive complaints in nearby offices. Diagnostic measurements proved that the major problem was an in-duct standing wave resonance in the manifold that was amplified by panel resonances in the filter enclosure.

The engineering solution involved:-

- designing an aerodynamic insert that was fitted in the ductwork to reduce turbulence

- fitting an acoustic absorbent plug into an end cap to create an anechoic termination to destroy the standing waves

- applying stiffening ribs to the filter enclosure to detune the noise radiating panels

These measures were fitted within a single day at very low cost to eliminate the low-frequency tones (a 30dB reduction).

Improving the LEV weld extract system performance

The first step in our approach to attenuate LEV fan noise is to develop modifications to improve the system efficiency as this also reduces noise (noise is wasted energy).

In this case, the aerodynamic modifications we designed to cut the noise also dramatically improved the fume extract fan system efficiency, improving safety and reducing running costs.

This approach based on our expertise in fan systems can be used to improve LEV extract efficiency, even where noise is not an issue...

View the detailed guide to fume and scrubber extractor fan noise reduction and silencing techniques.

Data centres (or "data centers" in the US) require a lot of cooling - which involves noisy chiller fans, air handling units (AHUs), cooling towers and condensers. Moreover, in addition to the general fan air noise, there are often low-frequency tonal elements (hums or drones) that cannot be silenced using conventional attenuators and acoustic enclosures and barriers. Unfortunately, poor diagnosis of the exact causes of noise complaints has often led to ineffective control of the noise from data centers that not only fail to solve the problem, but also compromise cooling efficiency.

Fortunately, there are effective low-cost alternatives that can actually increase cooling capacity...

Data centre noise problems - low-cost precision attenuation

A Noise Abatement Notice had been issued re the AHU noise from a large array of chillers at this data centre. The company had already spent nearly £100k on noise control with very little success and was considering claiming Best Practicable means (BPM) in court when the council suggested they might like to get a second opinion from us to avoid the legal route…

We carried out a very accurate diagnosis of the precise noise elements that were the cause of the complaints. Based on this evaluation, we designed a set of precise retrofit noise reduction measures that were guaranteed to be BPM. The innovative noise control measures included:

- Air handling units: changing the geometry of the AHUs and introducing internal modifications to convert existing elements into effective acoustic attenuators cut the broadband noise by >10dB(A) with no effect on fan efficiency

- Chiller condenser fans: the noise from these units was reduced by fitting a combination of high-efficiency damping coupled with internal and fan modifications, reducing the overall noise by around 8dB(A) with no effect on performance. Improvements were also made to the existing noise barriers.

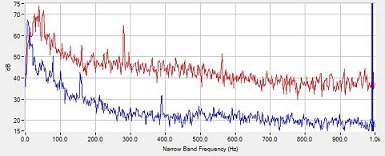

These noise mitigation measures cut the overall noise at the complainants from 48.5dB(A) down to 36.5dB(A) (as illustrated by the audio recording above and by this noise signature) without affecting the performance of the cooling systems. In addition to the reduced broadband noise, the tonal "character" of the noise was also eliminated.

The whole process took approximately 6 weeks from start to finish and completely resolved the complaint issue.

Cost savings on noise control

The overall effect was to reduce the data centre cooling system noise by 15dB at less than half the previously expected cost. If this approach had been implemented in the first place, the company would have saved over £100k, the council would have saved resources and the complainants would not have had to suffer unnecessary disturbance over a 2 year period.

More details on how to reduce environmental noise from data centers

More on chiller, condenser and heat exchanger AHU fan noise reduction.

Planning - noise site blight

High levels of environmental noise from nearby industrial premises were affecting over 18 acres of mixed brown-field and farmland. Combined with the fact that there had already been many noise complaints from nearby residents, the planners assessed the site as unsuitable for housing.

However, the City Council wanted to allow the development if the noise issue could be resolved. Aware of our expertise in industrial and fan noise control, they suggested that the Planning Consultants contact us for a second opinion to see if there was a practical solution.

Diagnosis

We acquired information from the council about the history of complaints and considered that it was very likely that it would be practical to reduce the noise across the site by applying permanent engineering noise control measures to the problem items of plant.

Noise control implementation

Based on our judgment, the developers invested in our expertise to evaluate the noise control options in detail and to design permanent solutions (including our Quiet Fan noise control technology for the problem fans) that could be implemented (paid for by the developer) at each of the 4 companies involved. The companies were extremely happy with the process as this resolved the previous and ongoing noise complaints at no cost to them.

The environmental noise environment for nearby residents was dramatically improved and the council saved on future noise complaint investigation resources.

The noise mitigation measures permanently eliminated the environmental noise problem, allowing the "noise planning blight" to be lifted. Consequently, planning consent was granted for 200 properties to be built on a site previously considered too noisy for housing. This not only made the site worth many £millions at a cost to the developers of less than £45k, but it also provided 200 much-needed houses.

Local residents were complaining about low frequency noise and vibration from a large tunnel operation which also exceeded the overall planning consent noise levels. The low frequency noise and vibration was generated by the spoil processing vibratory sieves and the previously proposed remedial measures included a deep ditch and a very large barrier. Neither of these would have been effective...

Our detailed diagnosis showed that the main problem was caused by excitation of some of the steel building wall and roof panels that then radiated the vibration very efficiently as noise. The panels we had identified as a problem were de-tuned quickly and cheaply by introducing stiffening ribs. This reduced the 15Hz noise radiation by 8dB which was sufficient to prevent further complaints.

We have also generated a comprehensive technical note on all aspects of vibratory feeder, hopper, conveyor and grader noise...

Complaints about press noise from a factory unit had resulted in an Abatement Notice from the Local Authority. After the company had spent over £12000 on the building to no avail and with another £65000 expenditure planned as recommended by noise consultants (but without any guarantee that it would solve the problem), they had decided to challenge the notice in court.

However, as our Best Practicable Means (BPM) Noise Control Audit for the Local Authority proved that the best solution was to treat the small number of power presses that were causing the issue at source at a fraction of the cost of legal fees, this approach was adopted by the company. The engineering source control measures reduced the low frequency noise components by 9dB - 24dB, eliminating further complaints. This is a classic case where consultants have not carried out detailed diagnostic work to identify the precise causes of complaints, who do not have the engineering skills needed to design source control modifications and are therefore limited to recommending conventional palliatives that are not best practice at a very high cost to the client, the LA and to the disturbed residents.